- JCO Pipe Forming Press

- Press Brake

- CNC Servo Press Brake

- CNC Press Brake

- Heavy Duty Press Brake

- Press Brake in Tandem

- Cute Press Brake

- CNC Torsion Press Brake

- Corrugation Plate Bending Line

- NC Press Brake

- Plate Bending Machine

- 4 Rollers Plate Bending

- Universal Plate Bending Machine

- Mechanical Plate Bending Machine

- Long Plate Bending Machine

- Asymmetric Plate Bending

- Shearing Machine

- Hydraulic Press

- Tube Bending Machine

- Ironworker

- Section Bending Machine

- Folding Machine

- Mechanical press

- Cut to Length Line

- Laser Cutting

- Parameters

- Pictures

- You May Like

- Inquiry Now

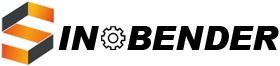

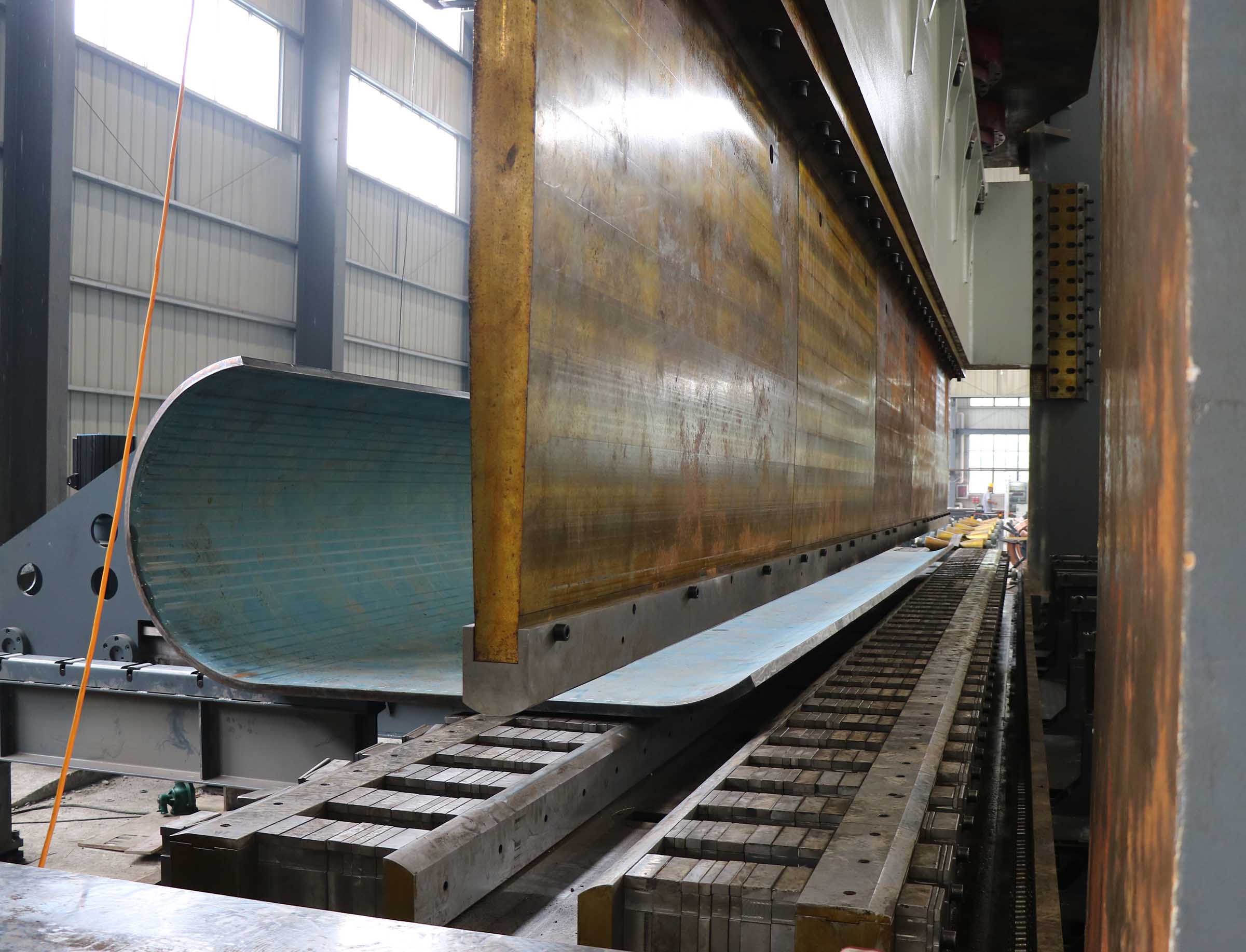

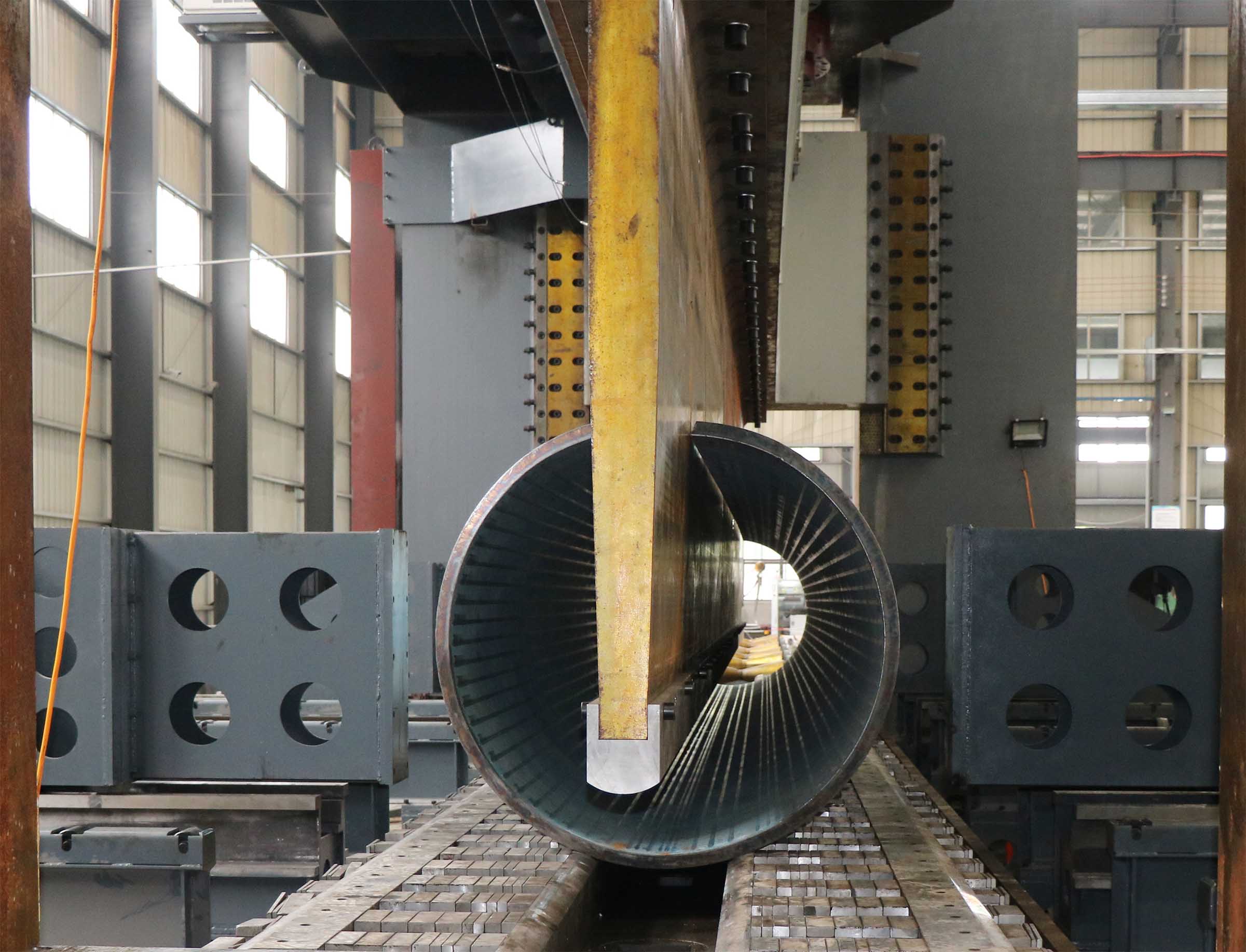

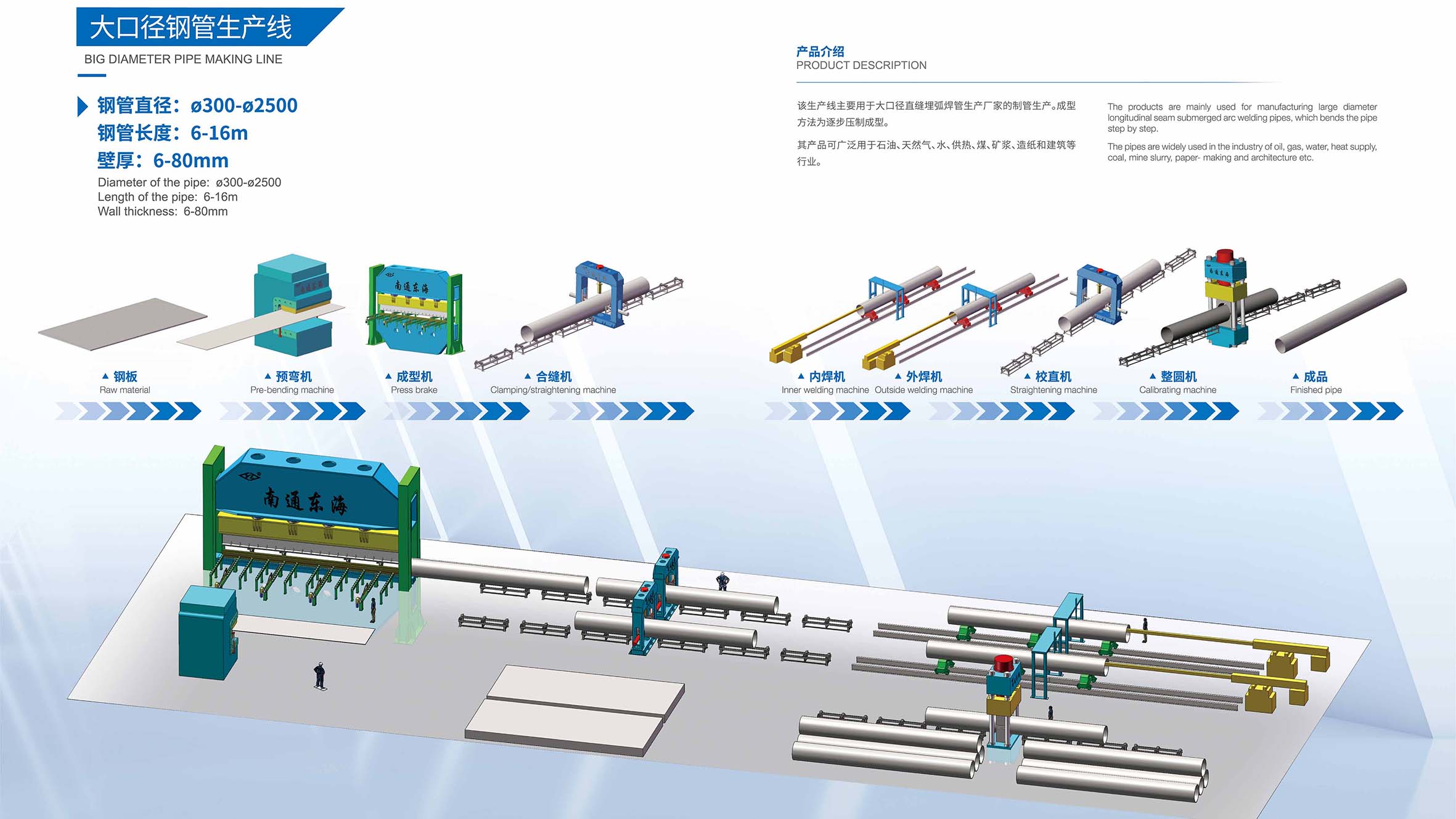

JCO-10000T12500 Pipe Making Machine

This JCO forming press enables precise form bending of longitudinally seam-welded pipes (LSWP). This pipe forming press represents a significant step forward in large-diameter pipe manufacturing, offering shape flexibility and numerous benefits for producers.

With advanced structure and control systems, this JCO forming press ensures the production of diameters ranging from 16 to 64 inches, wall thicknesses exceeding 80 mm and the length reach the 12.5 meters or even more. This flexibility enables pipe manufacturers to cater to diverse demands with quality standards.

Parameters

|

|

Specification |

Parameter |

|

Remark |

|

|

1 |

Rated force |

100000 |

KN |

|

|

|

2 |

Length of table |

12500 |

mm |

|

|

|

3 |

Distance between columns |

12800 |

mm |

|

|

|

4 |

Bending length |

8000-12200 |

mm |

|

|

|

5 |

Max.daylight |

2580 |

mm |

Max.Φ1800 |

|

|

6 |

Side throat depth |

2000 |

mm |

|

|

|

7 |

Beam stroke length |

500 |

mm |

|

|

|

8 |

Max. V of die |

800 |

mm |

|

|

|

9 |

Number of cylinders |

6 |

piece |

|

|

|

11 |

Power of servo motor |

6×90 |

KW |

INNVOICE |

|

|

12 |

Capacity of pump |

6×160 |

L/min |

|

|

|

13 |

Max. pressure of hydraulic |

25.5 |

MP |

|

|

|

14 |

Beam speed |

Approaching |

60 |

mm/s |

|

|

Bending |

6 |

mm/s |

|

||

|

Returning |

60 |

mm/s |

|

||

|

15 |

Overall dimension |

Length |

16200 |

mm |

|

|

Width |

5800 |

mm |

Without feeder |

||

|

Height |

10260 |

mm |

Overground |

||

|

5800 |

|

Underground |

|||

Features

▲ highly productive, accurate to make the small diameter but thick wall pipe

▲close loop proportional hydraulics for beam synchronization

▲REXROTH highly precise proportional valve to control accurate beam movement

▲ accurate & fine beam position control by micro limit switch.

▲CNC controlled front feeder/back gauge

▲motorized side discharger

▲moviable lower die to bend the end of the plate

▲variable-V die to suit to different thickness plate

▲FAGOR lineal scale

▲servo motor

Bending step

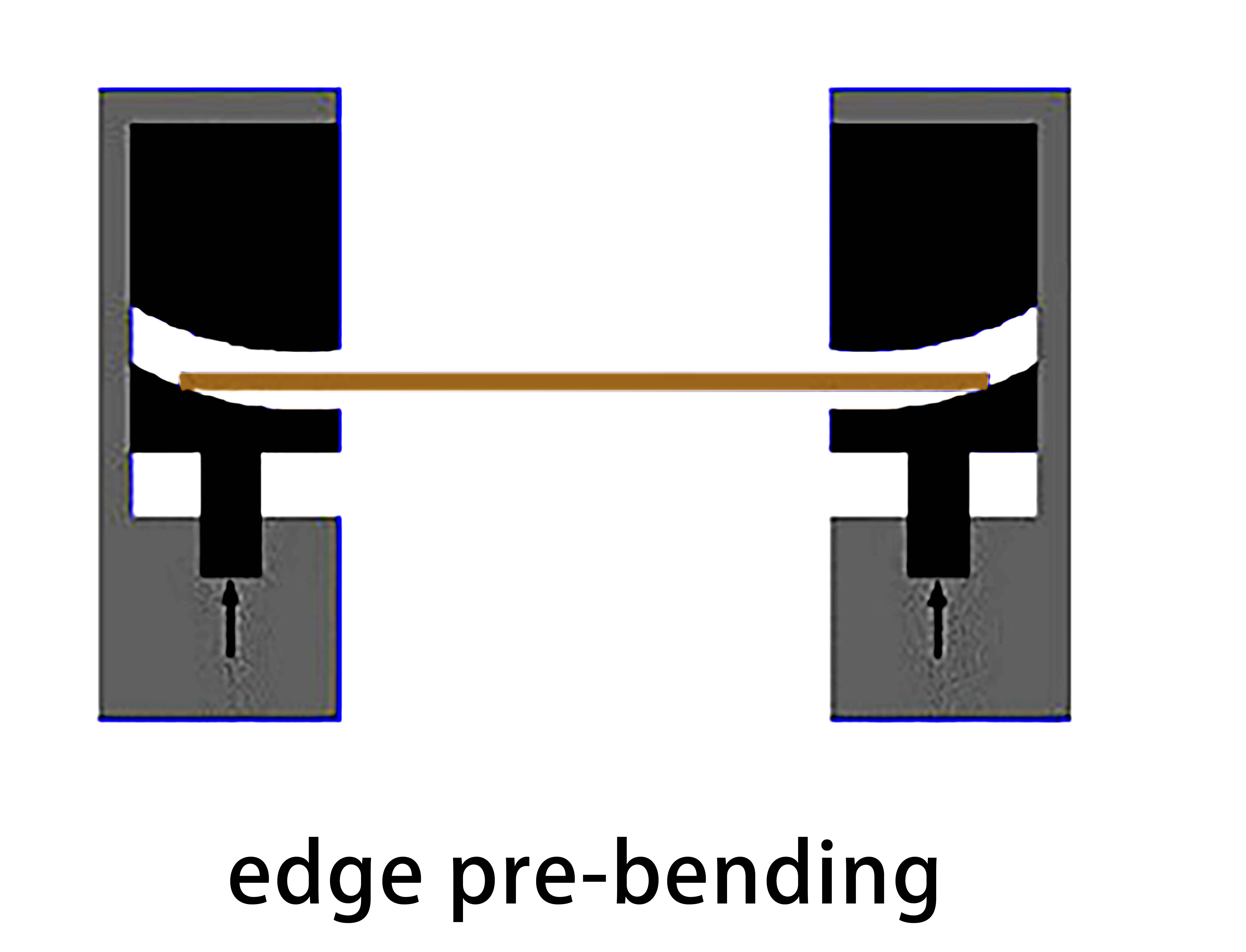

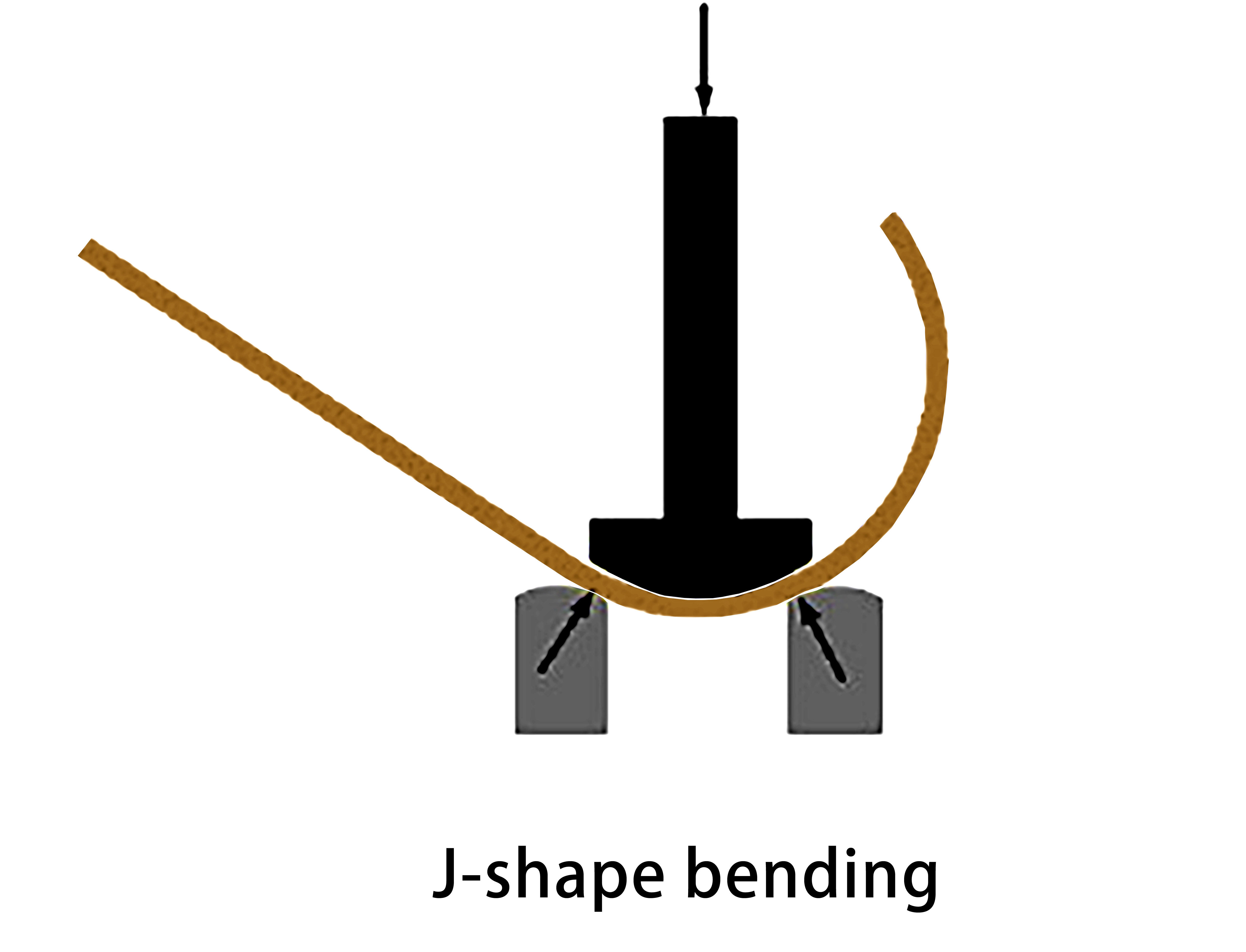

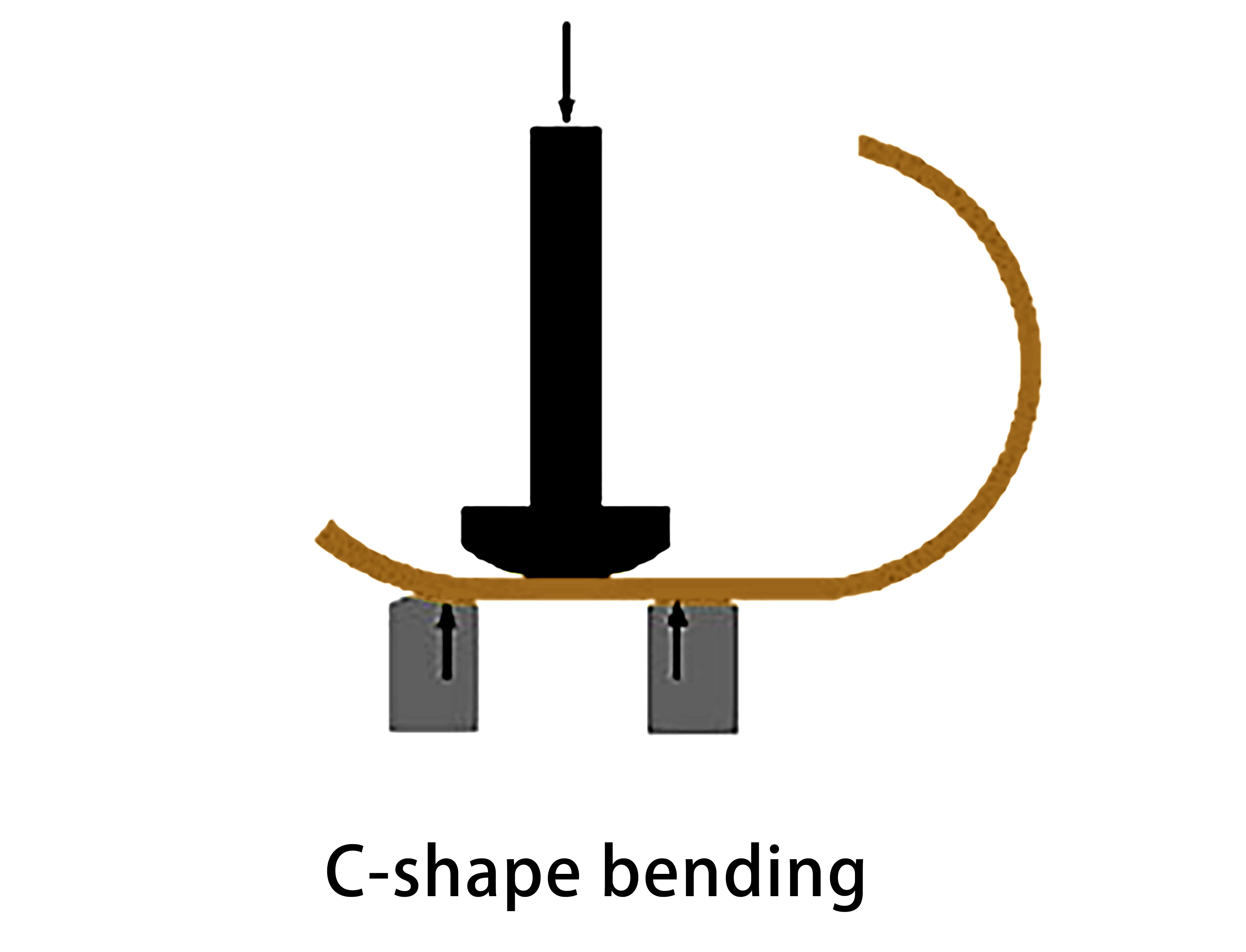

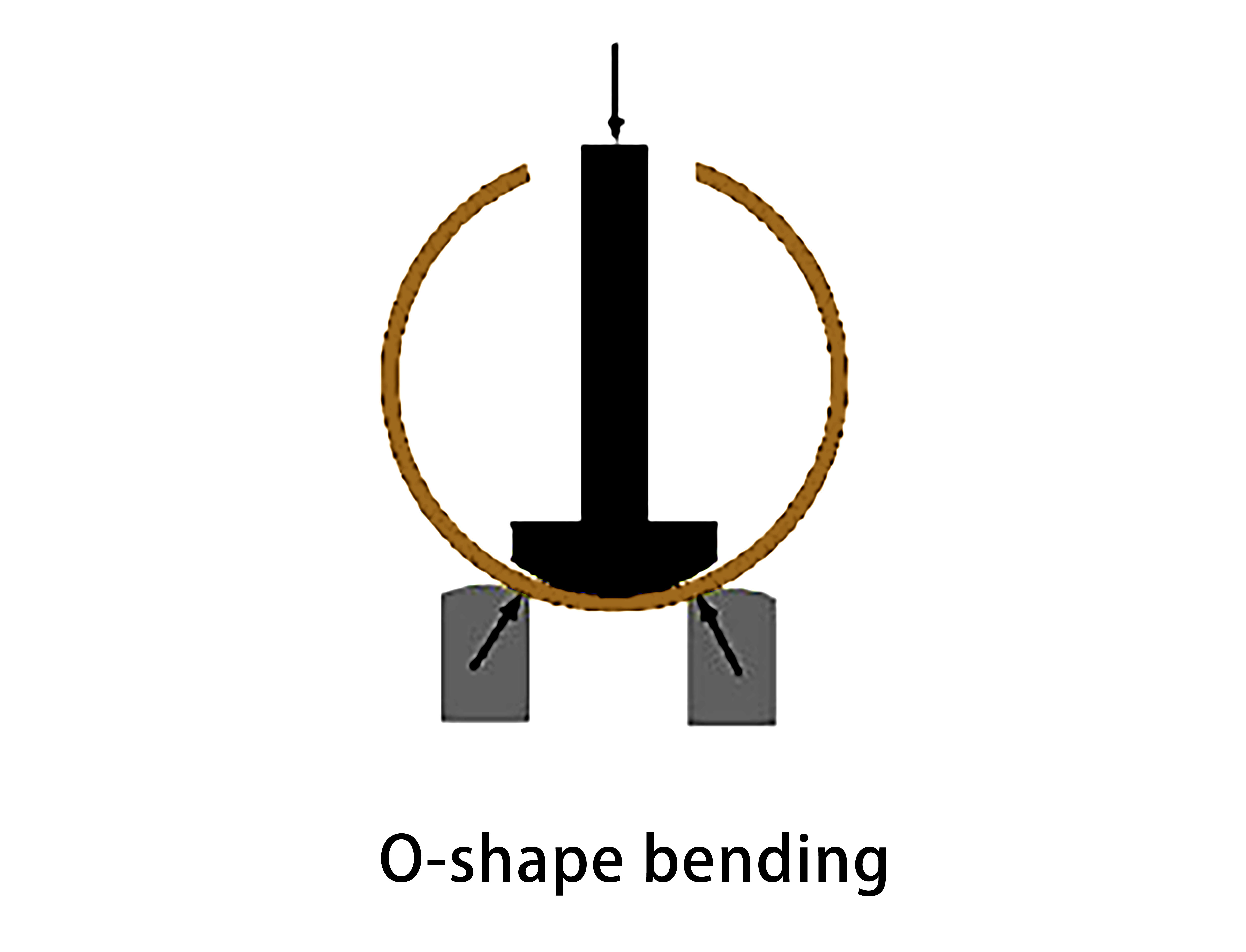

JCO forming means that the steel plate is bent into a cylinder after four steps:

--First, the edge of the steel plate is pre-bent into an arc shape

--Second, one side of the steel plate is stamped on the stamping equipment in multiple steps to form a “J” shaped plate

--Third, the other side of the steel plate is bent in the same way to form a “C” shape

--Forth, the middle part of the steel plate is pressed down to form an “O” shape of the opening

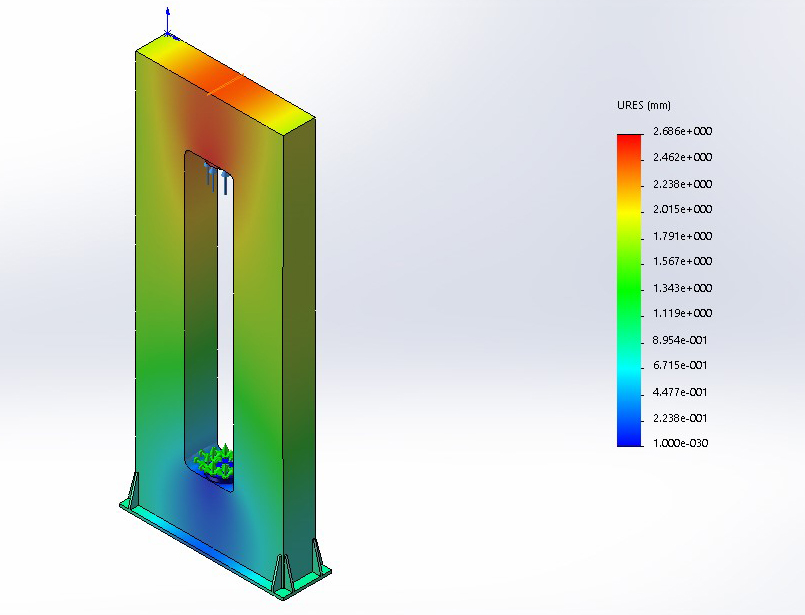

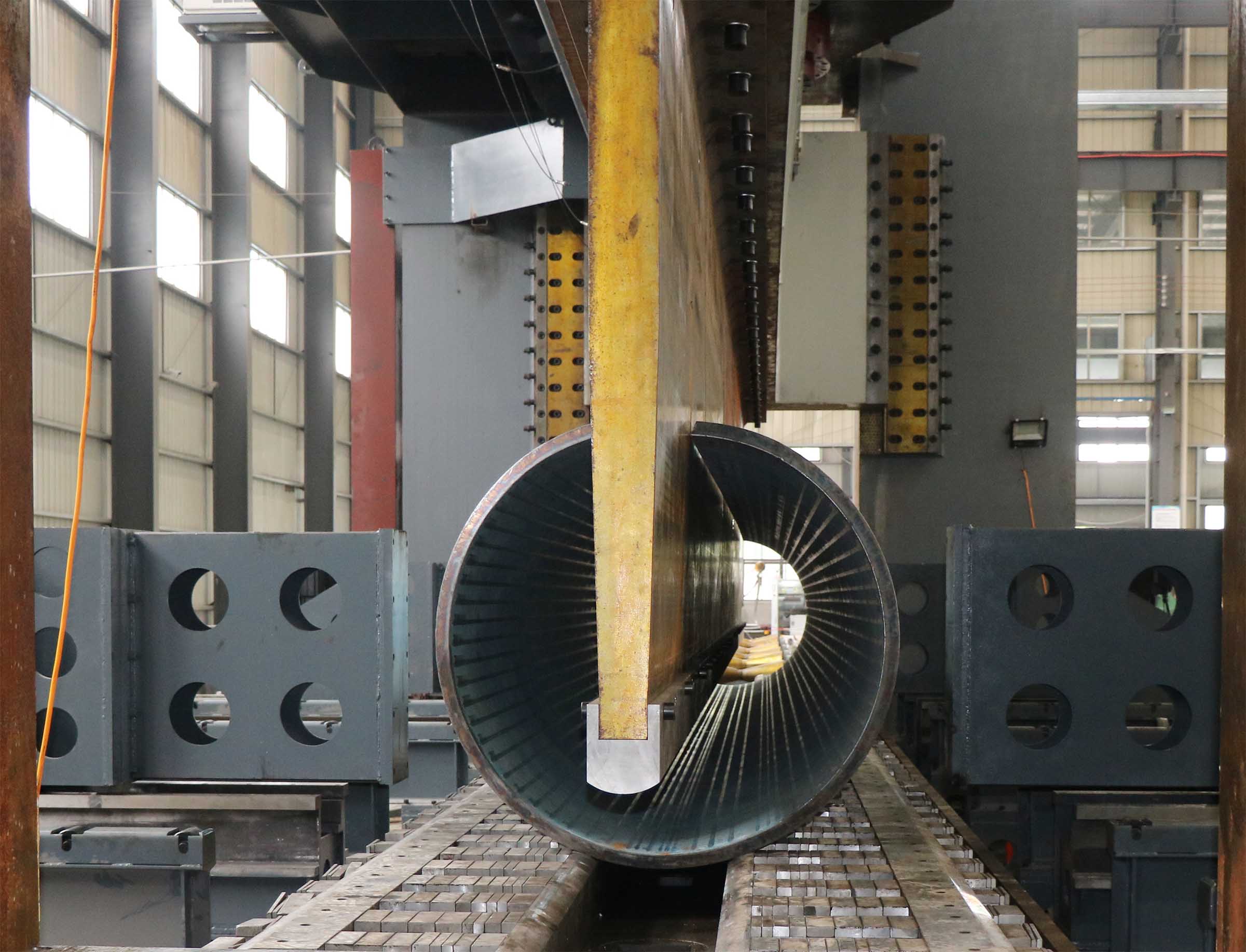

Main frame

--Hydraulic system

This JCO press is equipped with variable speed pumps (VSP) and hydraulic systems, ensures efficient production while minimizing energy consumption by up to 50% compared to conventional systems.

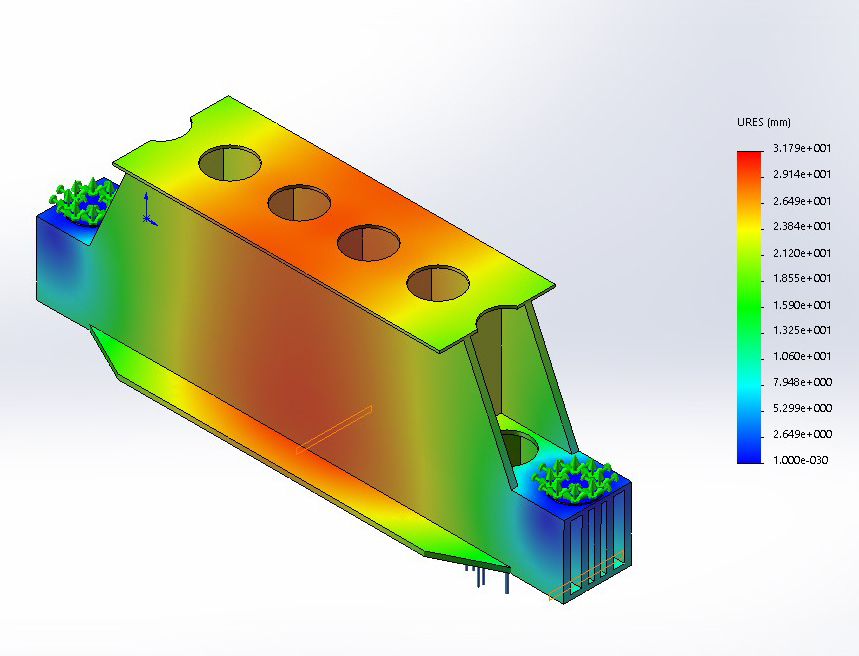

Cylinder

Variable lower die

Variable lower die, Max.V=800mm

Movement die

The die can move in horizontal, to pre-bend the end of the plate.

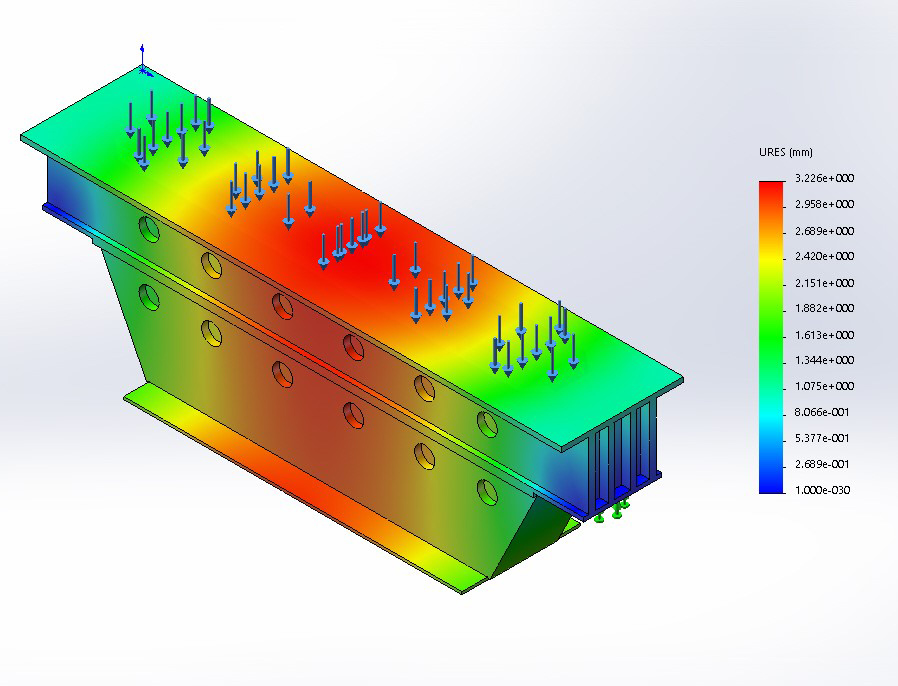

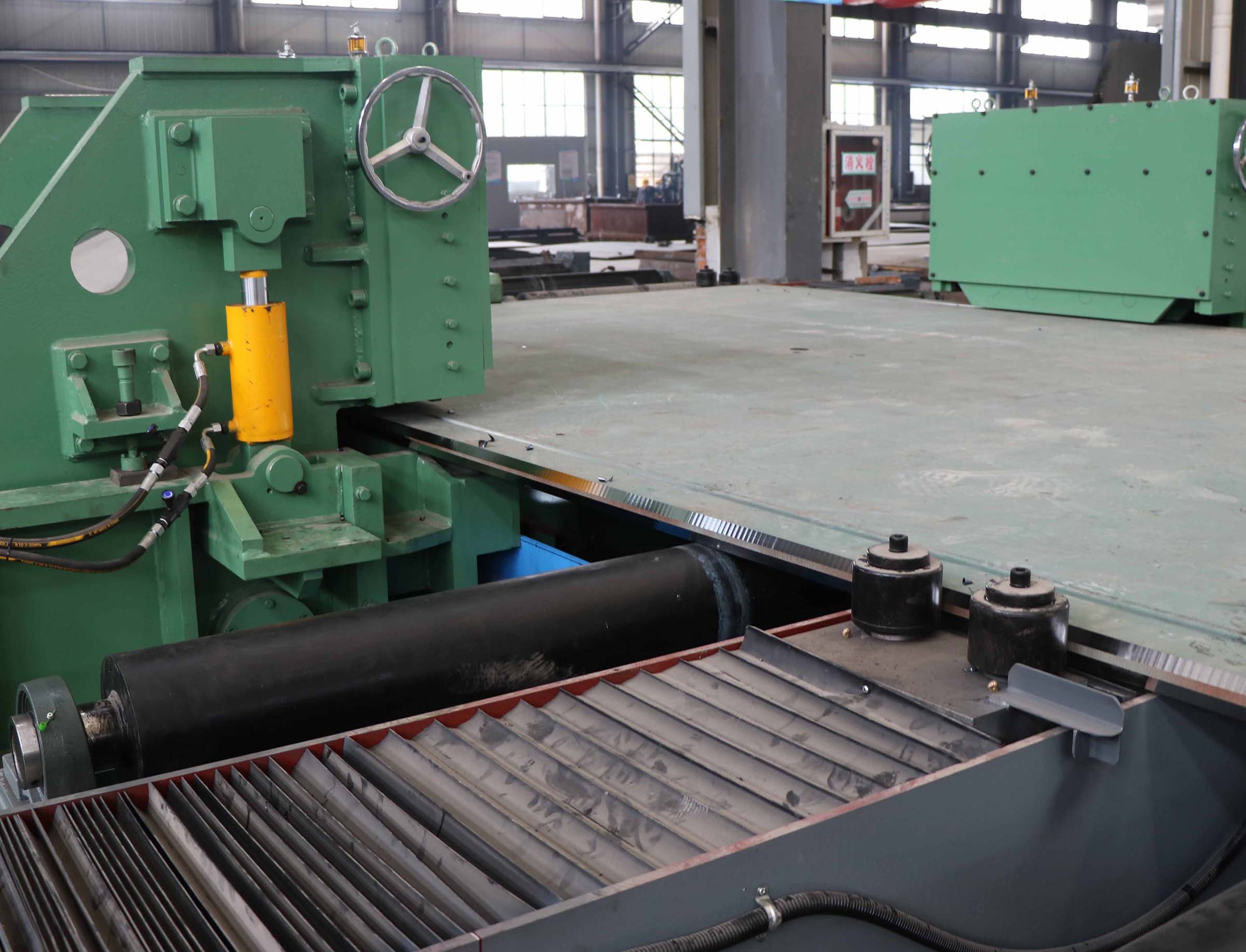

CNC controlled front feeding system

Max.feeding range:6000mm

CNC controlled back gauge

Max.feeding range:6000mm

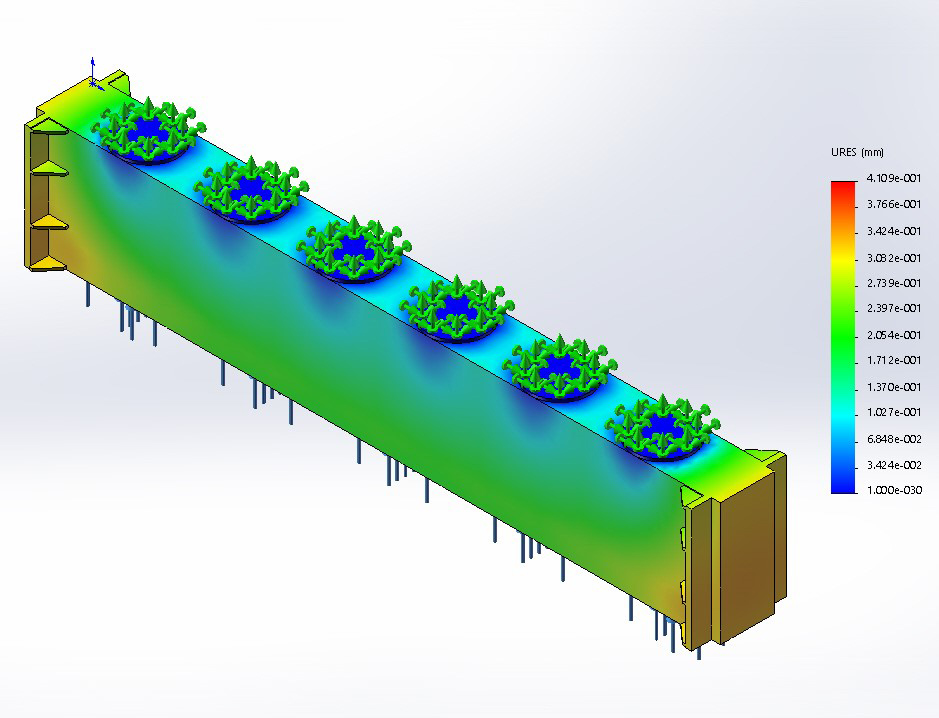

Motorized feeding pathway

Side discharger

Optional

--Edge chamfering

--Clamping/straightening

--Inner welding machine

--Out welding machine

Pipe making machine, press brake, clamping, straightening, innwer welding, out welding