- JCO Pipe Forming Press

- Press Brake

- CNC Servo Press Brake

- CNC Press Brake

- Heavy Duty Press Brake

- Press Brake in Tandem

- Cute Press Brake

- CNC Torsion Press Brake

- Corrugation Plate Bending Line

- NC Press Brake

- Plate Bending Machine

- 4 Rollers Plate Bending

- Universal Plate Bending Machine

- Mechanical Plate Bending Machine

- Long Plate Bending Machine

- Asymmetric Plate Bending

- Shearing Machine

- Hydraulic Press

- Tube Bending Machine

- Ironworker

- Section Bending Machine

- Folding Machine

- Mechanical press

- Cut to Length Line

- Laser Cutting

- Parameters

- Pictures

- You May Like

- Inquiry Now

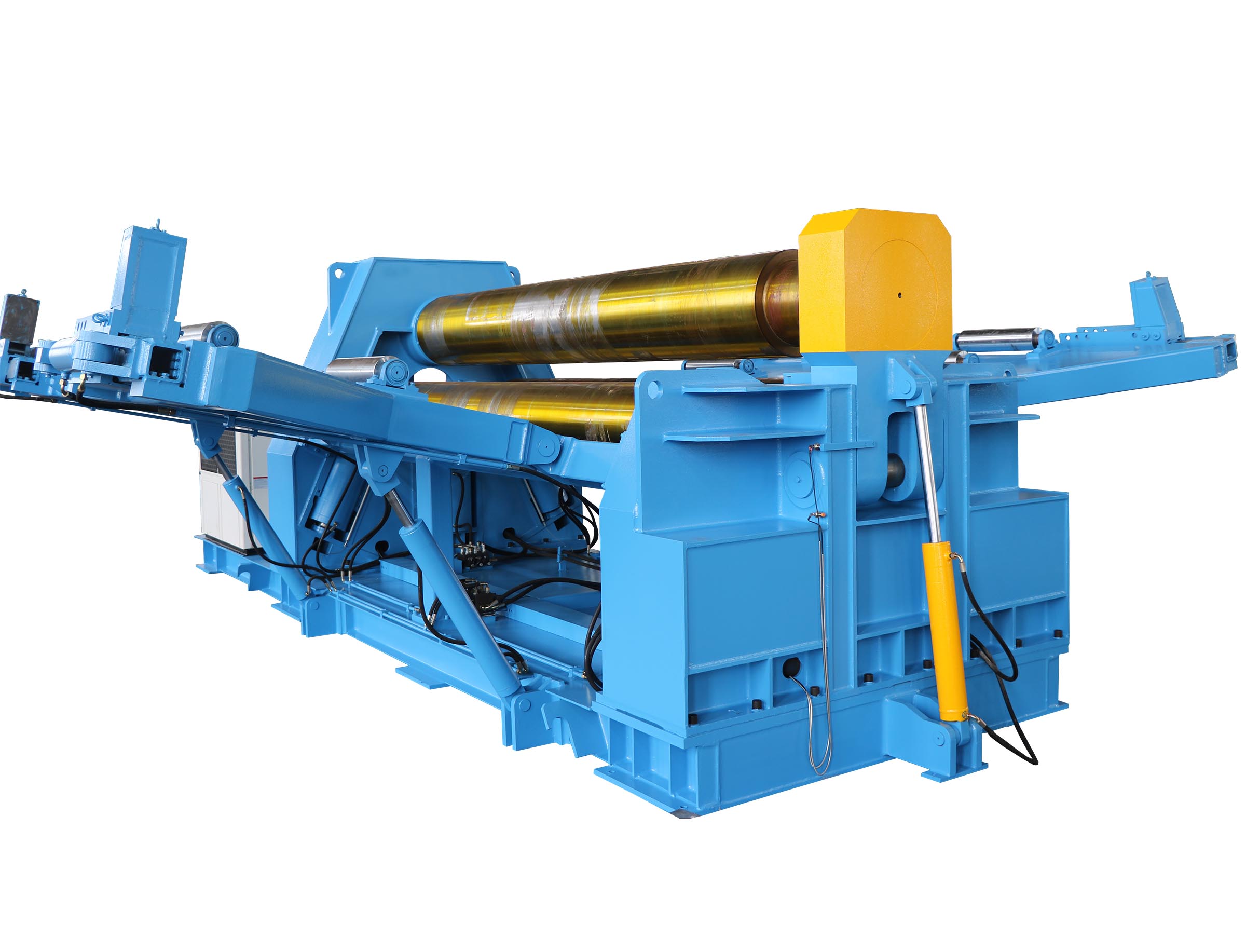

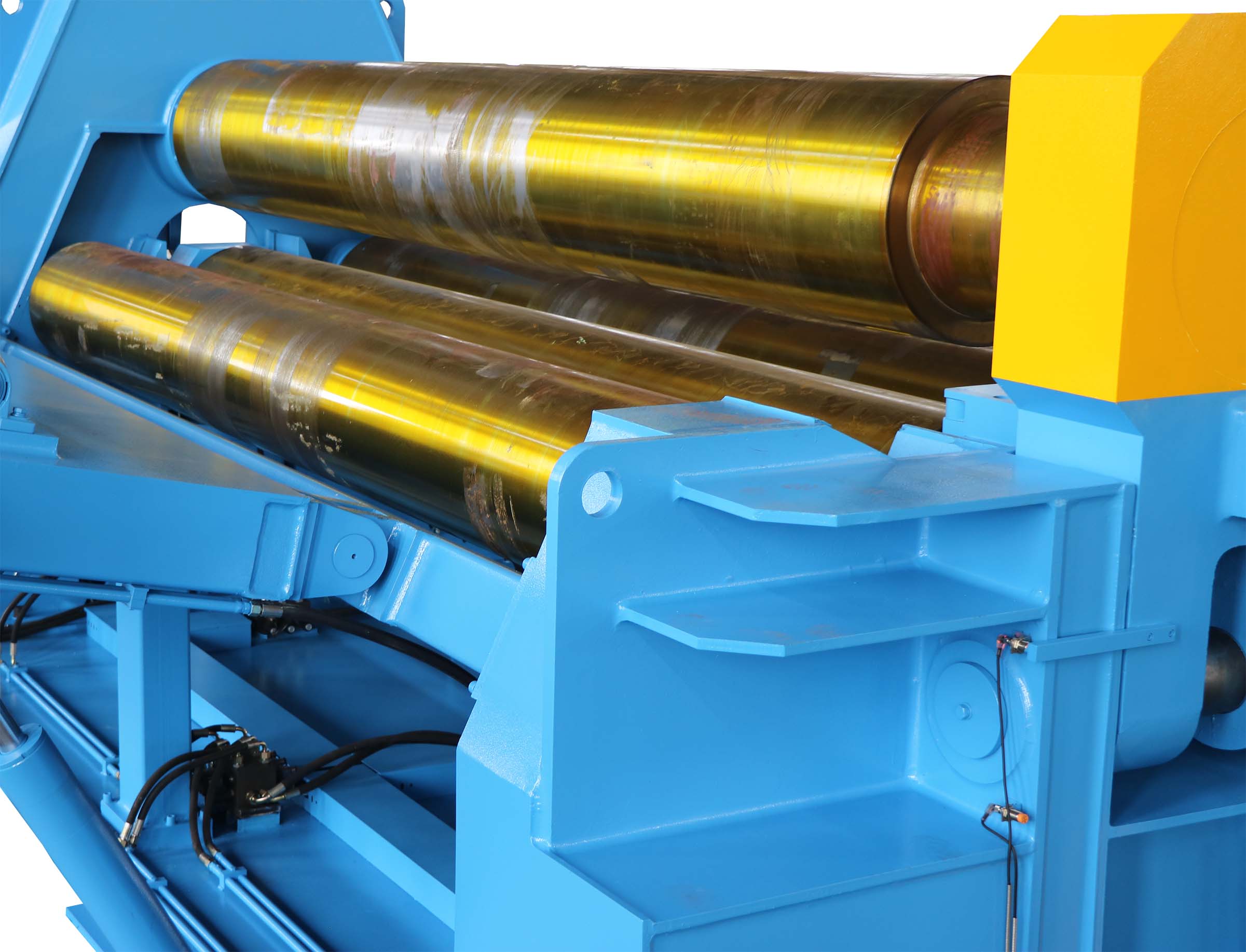

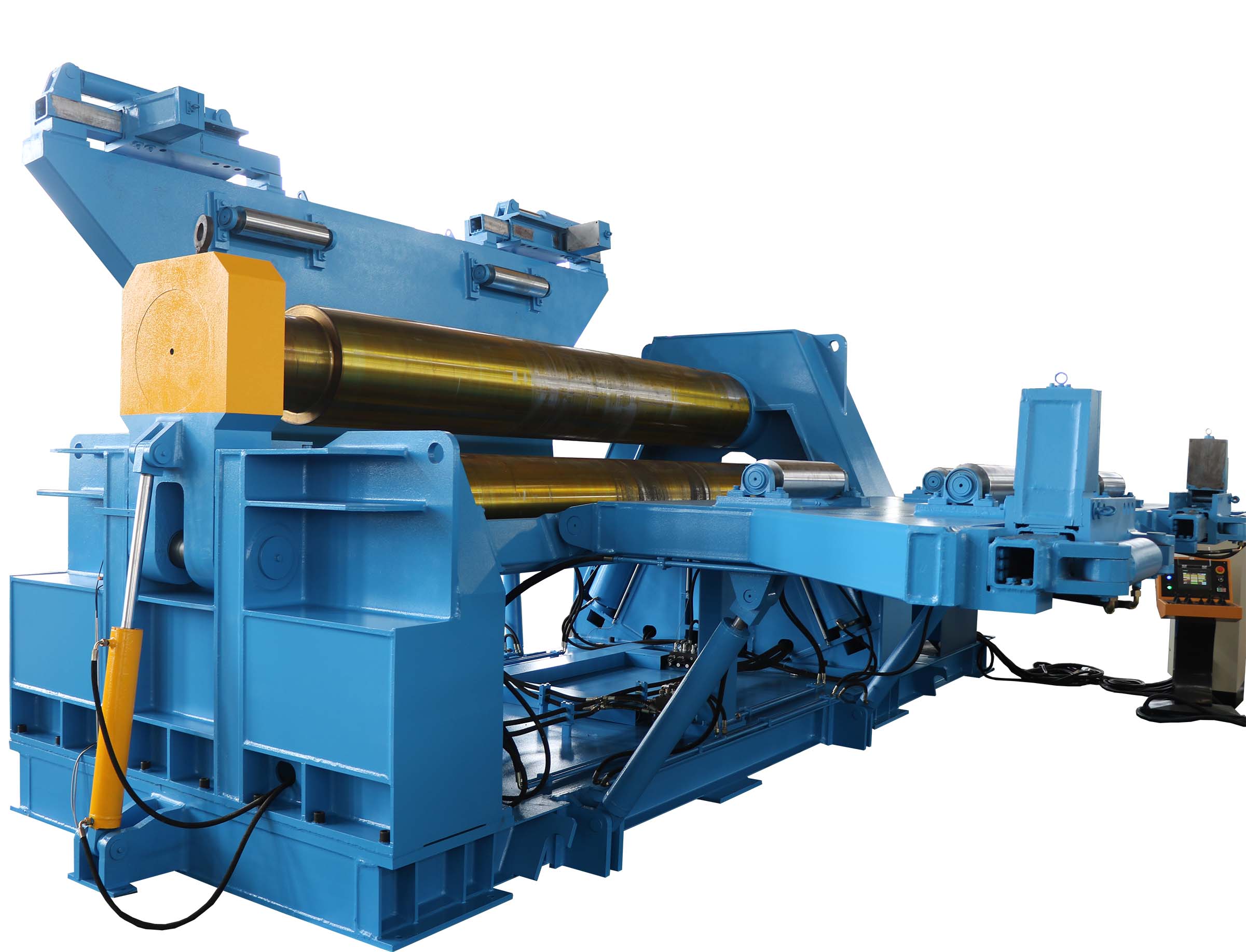

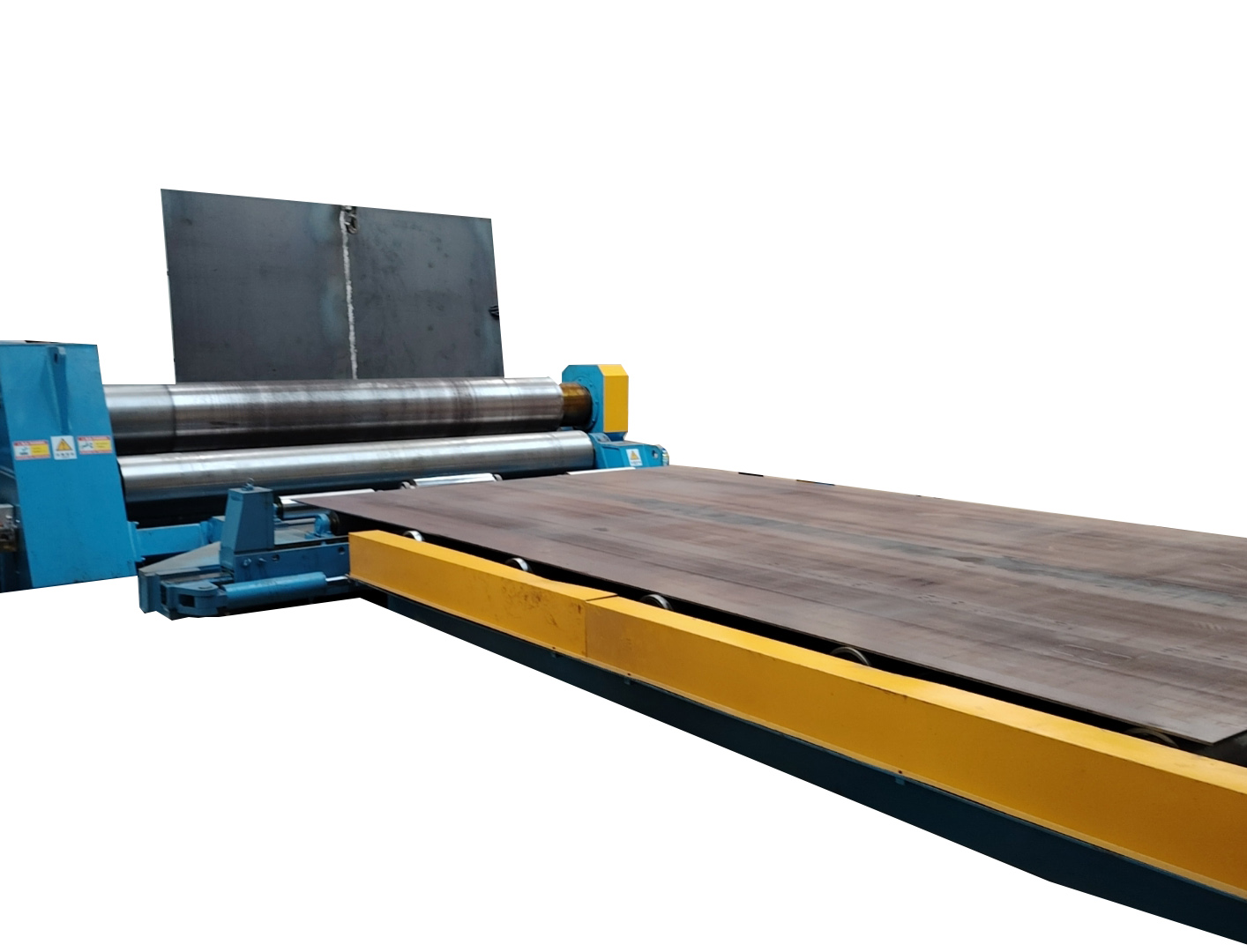

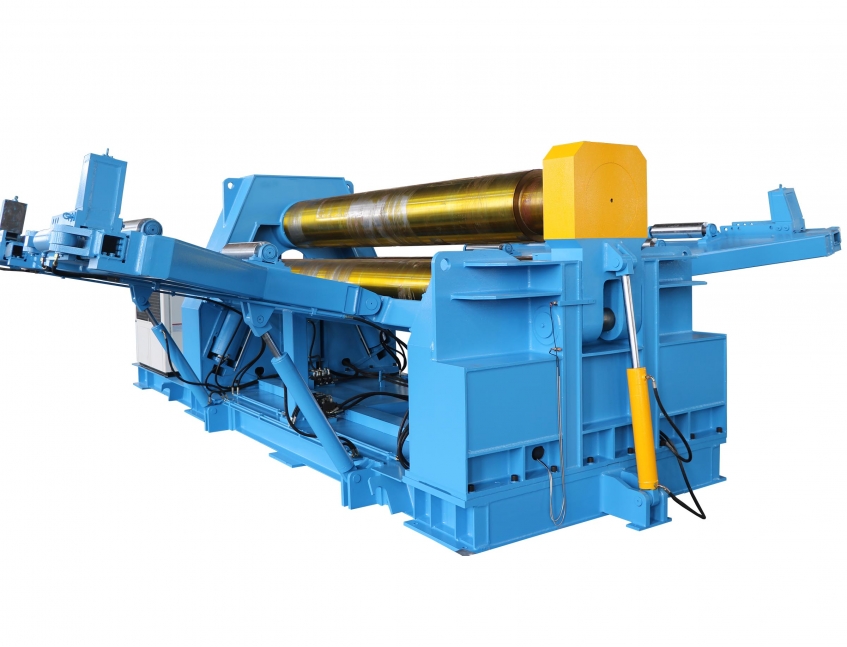

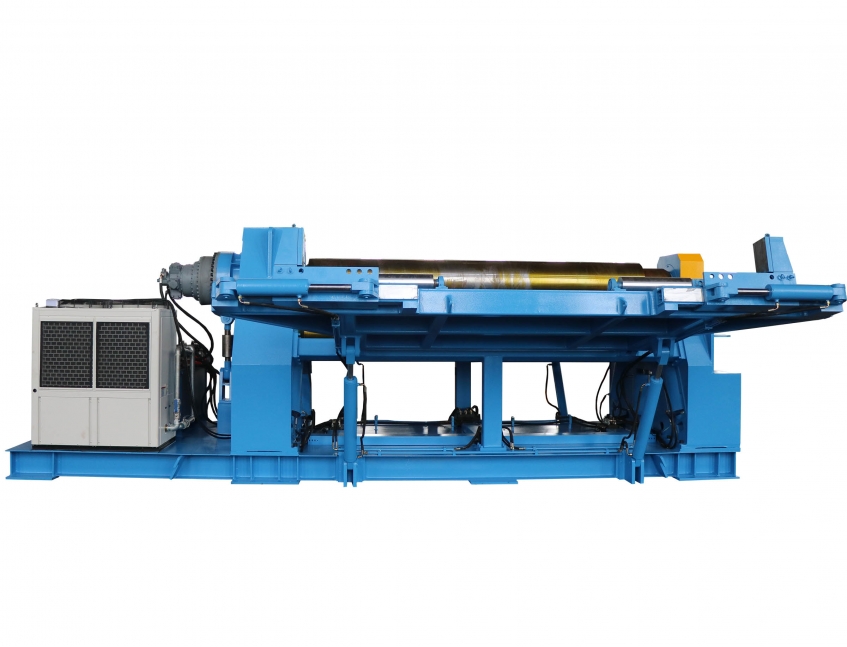

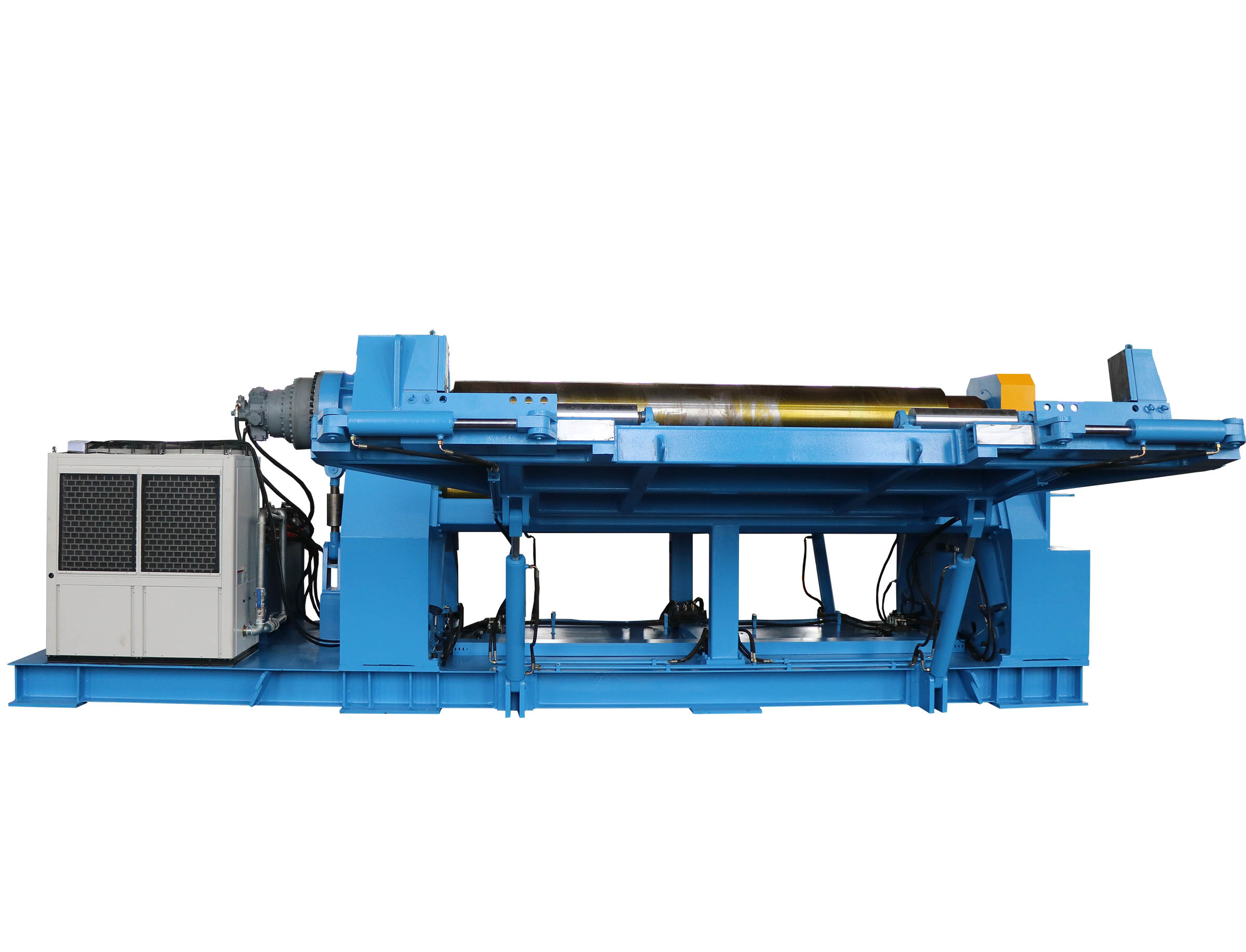

W12NC-30x4000 Four Rollers Plate Bending Machine

W12NC-30x4000 4-roller Plate Bending Machine is a type of double pinch plate bending machine. Each of the rollers is separate driven. Rollers rectilinear slide ways coated with antifriction material, no maintenance, suit to heavy duty loading, smooth and stable positioning. Spherical roller bearings are equipped on the rollers. All of the rollers in alloyed steel are induction hardening and heat treatment. All of the rollers will be grinded and polished after induction hardening treatment.

Parameter

|

Specification |

||||

|

Max. |

Thk. of bending plate |

(mm) |

30 |

|

|

Thk. of pre-bending |

24 |

|||

|

Width of bending plate |

4000 |

|||

|

Effective length of the rollers |

(mm) |

4100 |

||

|

Yield Strength of Plate |

(MPa) |

235 |

||

|

Min. reel dia. with max.size |

(mm) |

2000 |

||

|

Diameter of Roller |

Upper |

(mm) |

560 |

|

|

Bottom |

540 |

|||

|

Side |

460 |

|||

|

Roller |

Material |

42CrMo |

||

|

Hardness |

(HB) |

220-260 |

||

|

Induction Hardened Roll |

YES |

|||

|

Roll Profile |

crown |

|||

|

Lifting Mode |

hydraulic |

|||

|

Lifting Synchronous Precise/Accuracy |

±(mm) |

0.2 |

||

|

All Bearing Brand |

Self aligning roller bearing |

|||

|

Conical Bending Device |

YES |

|||

|

Driving Mode |

hydraulic motor |

|||

|

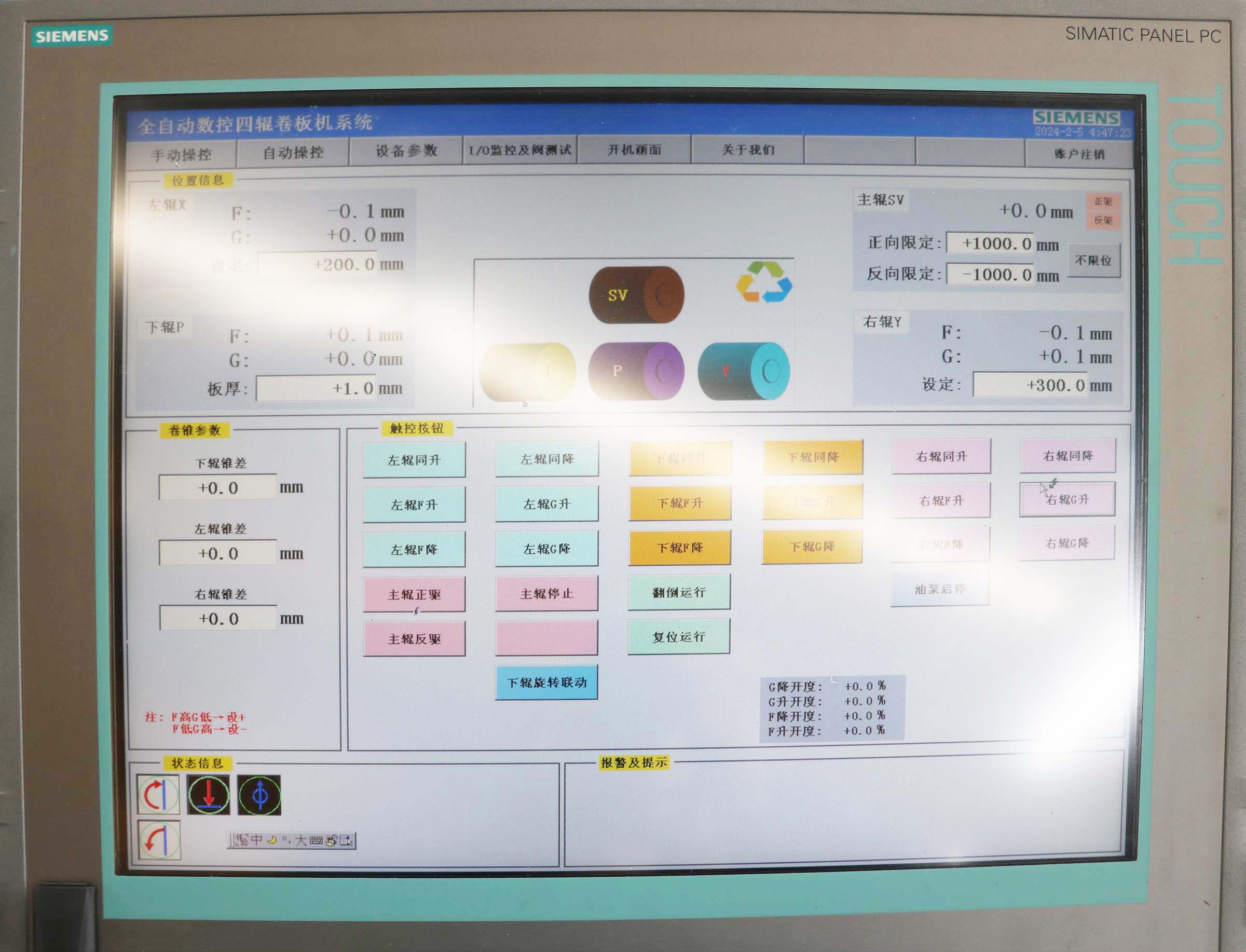

Control System |

Control Mode |

NC/CNC |

||

|

Display of position & displacement |

LCD |

|||

|

PLC |

SIEMENS |

|||

|

Electrical Part System |

SIEMNENS |

|||

|

Plate Bending Speed |

(m/min) |

about 3.5 |

||

|

Descending/Ascending Speed of bottom roller |

(mm/min) |

About 160 |

||

|

Descending/Ascending Speed of side roller |

(mm/min) |

About 300 |

||

|

Hydraulic System |

Max. Working Pressure |

(MPa) |

20 |

|

|

Valve |

YUKEN |

|||

|

Seal |

VALQUE |

|||

|

Electrical & Hydraulic Protection Againts Overload |

YES |

|||

|

Construction Steel Material |

Q235 |

|||

|

Side Support for Big Sheet Metal Diameters |

optional |

|||

|

Central Support for Big sheet Metal Diameters |

optional |

|||

|

Feeding Table |

optional |

|||

|

Oil Cooler System |

optional |

|||

Features:

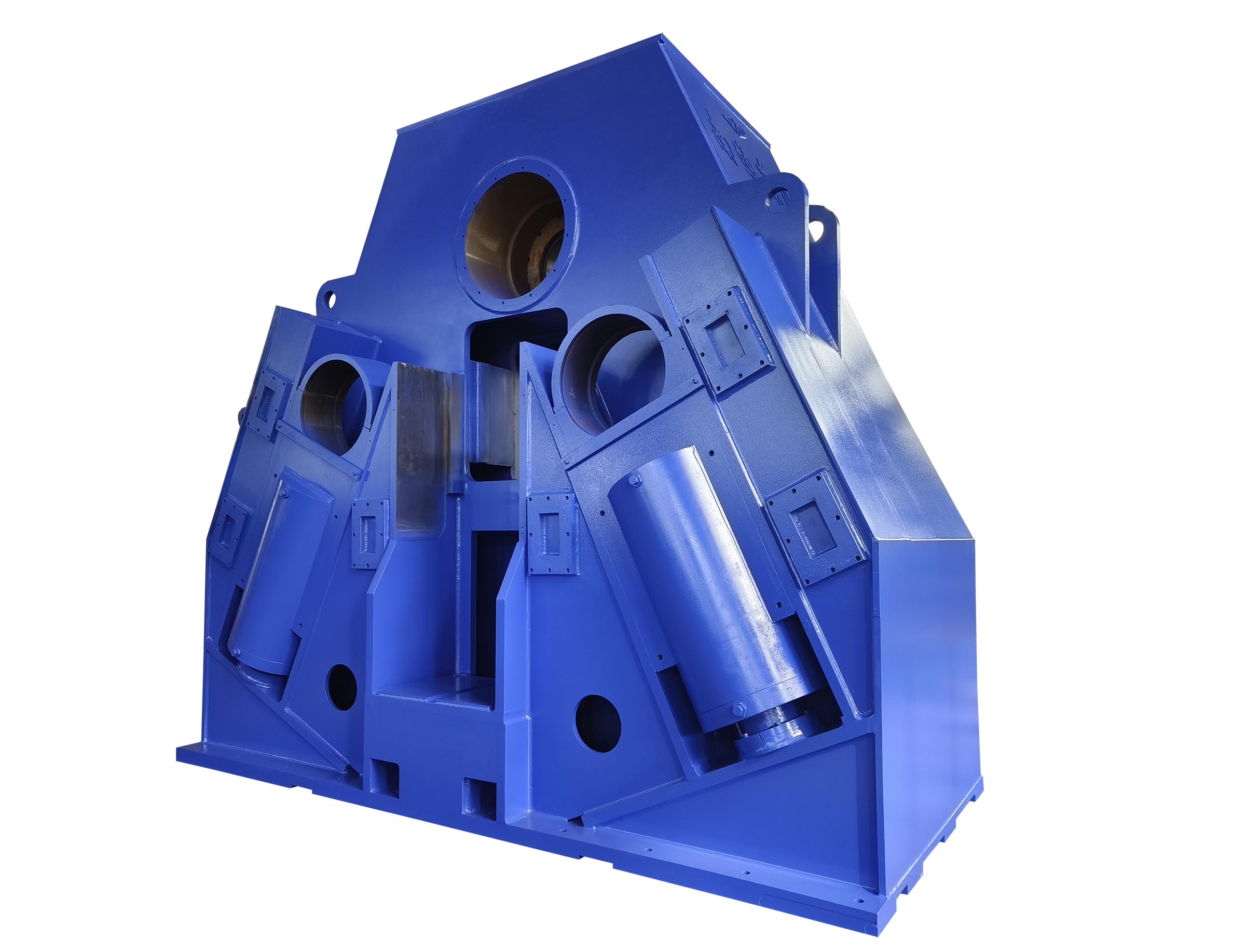

--heady duty linear sliding guides mounted on the uprights of the machine for lower roller and side rollers translation

--electronic parallelism control system

--rollers synchronization and balancing control fully electronically controlled

--side rollers and bottom rollers variable tilting controlled, positive or negative

--conical facility

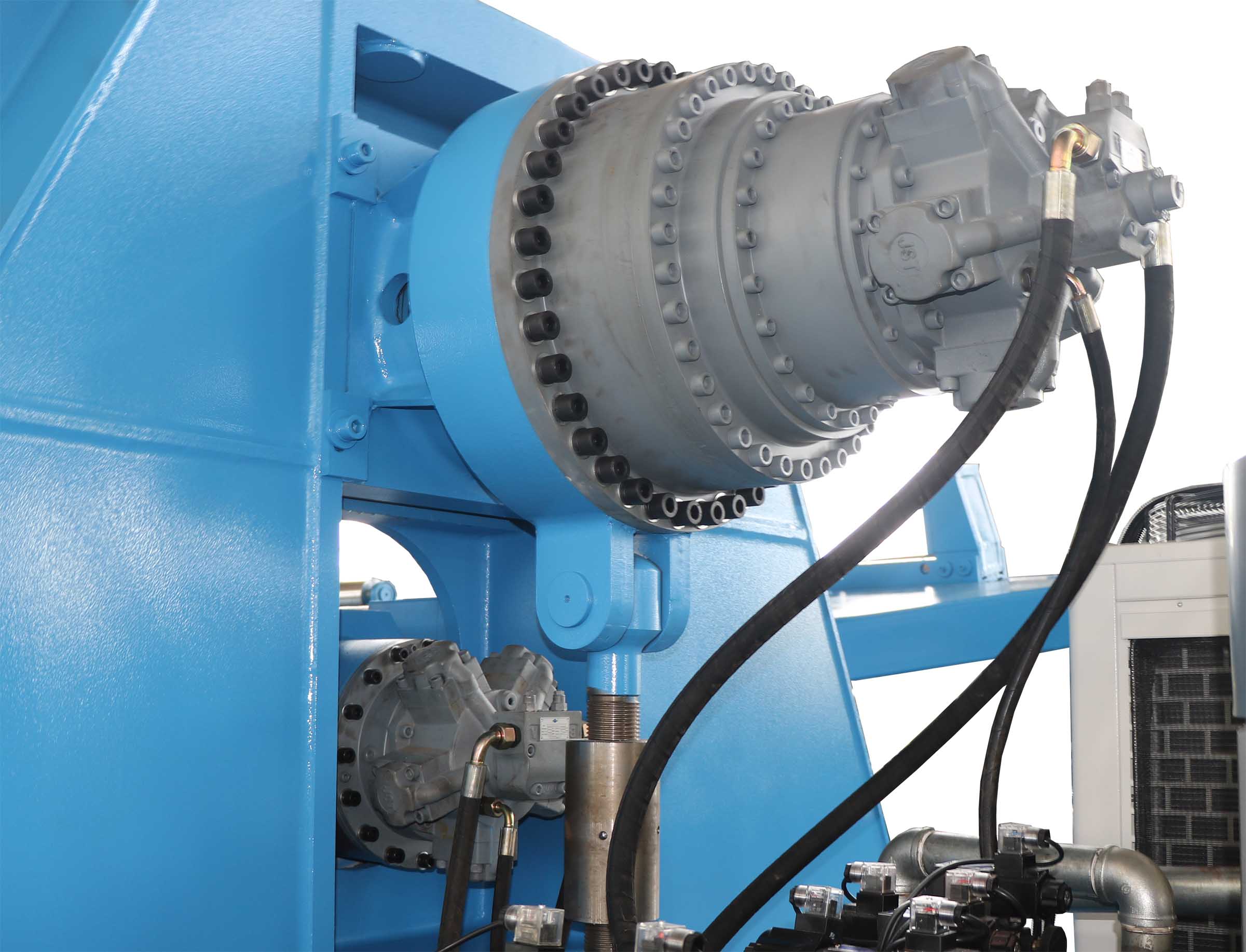

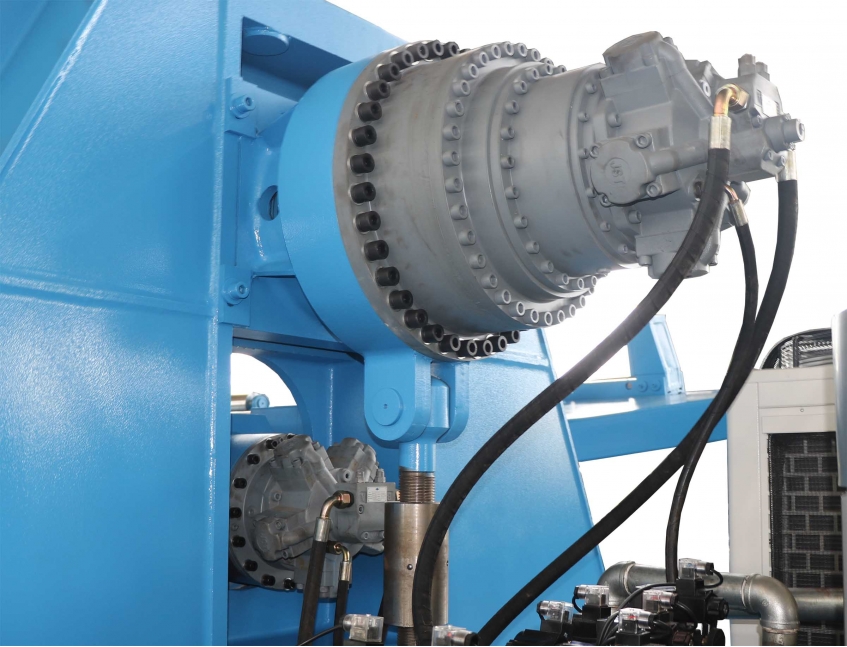

--rollers driving by independent hydraulic motors

--anti-friction material in sliding area

--instantaneous brake for rollers rotation for high safety

--reversal side hydraulic driving

--Mobile control panel station, with low voltage control

--Mobile control push-buttons, convenience for operator

--Rollers

.jpg)

--driving system

--SIMENS PLC

-- Hydraulic system

--Frame

--Cone bending

Optional:

--vertical plate supporting device

--side plate supporting device

The side supporting device assist in ensuring that the thin or big diameter size plate sheet remains in alignment and prevents sagging downward during the roll bending process.

This help to avoid any deformities or deviations in the final product.It also helps to let the operation easy, especially during the feeding period.

--feeding table

The feeding table and alignment system is quipped on one side of the machine so that the raw material can be automatically feeding and aligned

--Application

-268x205.jpg)