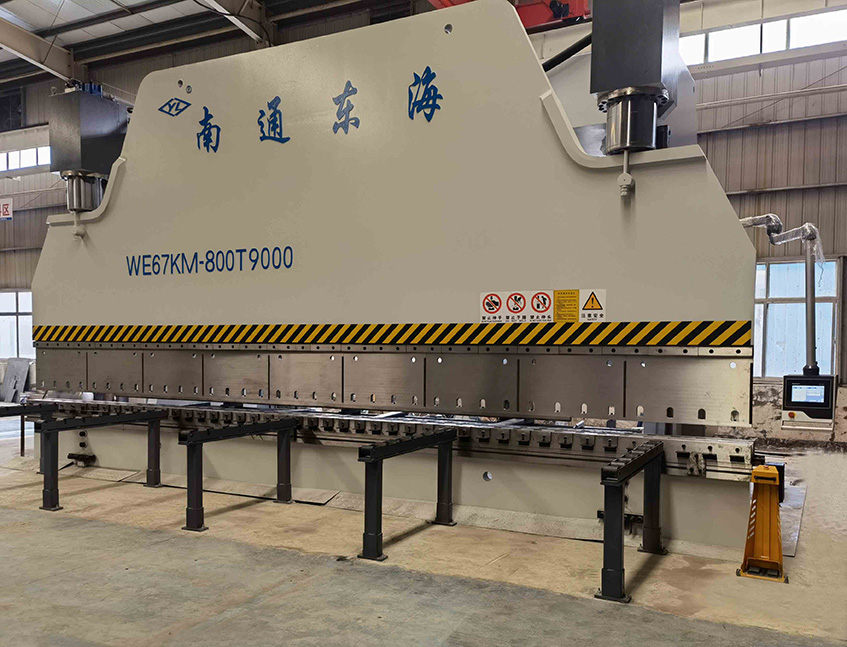

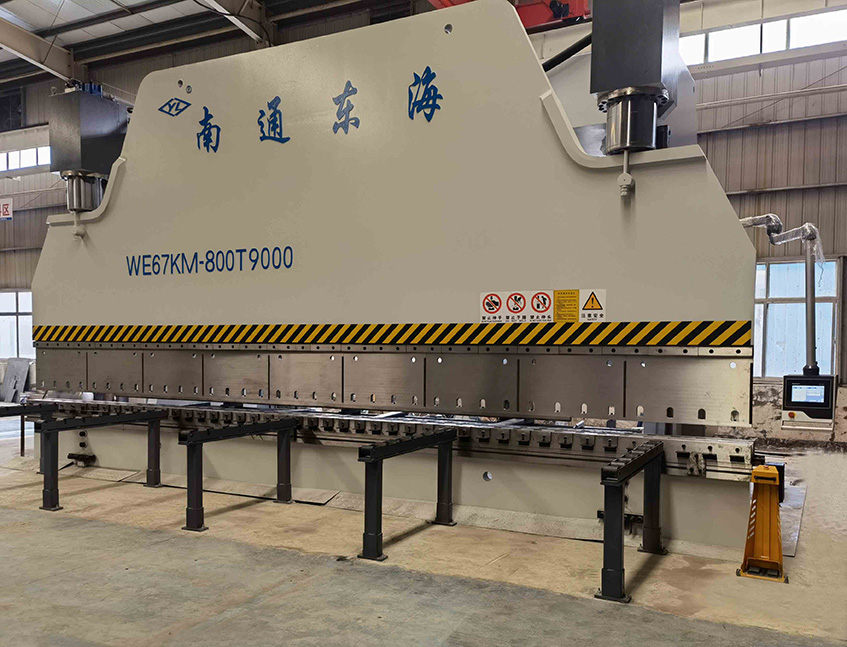

WE67KM- 800/9000 CNC Servo Press brake

Parameters

|

Model |

Rated Force (mm) |

Bending Length (mm) |

Distance of Uprights (mm) |

Daylight (mm) |

Throat Depth (mm) |

Beam Stroke (mm) |

Motor Power (KW) |

Dimenssions (L x W x H) |

|

WE67KM-800T9000 |

800T |

9000 |

6880 |

1250 |

1100 |

600 |

2X31 |

9400X3500X6180 |

Features

▲ 60%-70% energy consumption

▲ 30% oil consummation

▲ moving control panel with on/off controls, emergency push button &selector for inching,

▲oil tanker that connect with the cylinder

▲3+1 axis

▲CNC controlled mechanical pulling-rod anti-crowing device(V)

▲FAGOR linear scale to avoid the deflection bending

▲DA53T CNC control system

▲liner motion bearings and AC servo drive for accurate position up to 0.05 mm.

Instruction of structure

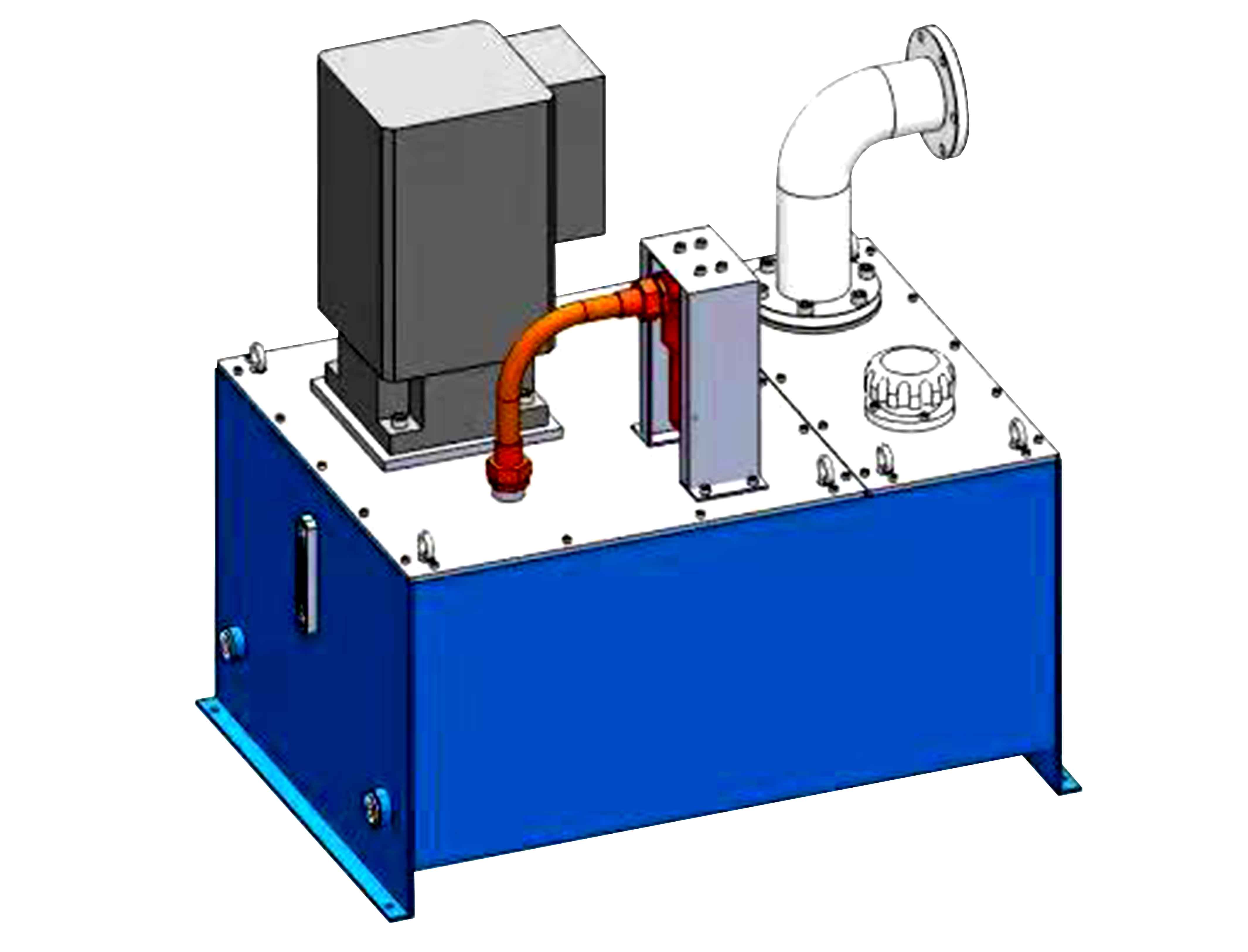

--Dual servo pump + motor

The servo motor doesn’t rotate when the press brake does not work; The servo motor is rotating during the bending and returning period, and the energy consumption is 60%-70% compare to the traditional press brake.

The hydraulic unit that connected to the cylinder directly, each hydraulic unit contains one servo motor and one oil container, the oil consummation is 30% of the oil that used in traditional press brake. It has the quickly action response, which let the beam move fast to improve the efficiency.

--CNC control system

The control system is DELEM D series professional press brake CNC control system, touch screen, 2D or 3D graphic.

--CNC crowning system

The mechanical wedge crowning device is placing under the lower die, using professional reducer and precision potentiometer to control the accuracy.

-- back gauge (X axis)

The back gauge is equipped with ball screw and linear rail.

The functions of the back gauge can be extended up to 6 axis ((X1,X2,R1,R2,Z1,Z2).

The functions of the back gauge can be extended up to 6 axis ((X1,X2,R1,R2,Z1,Z2).

--Tool

Variable lower die

#CNC, #pressbrake, #CNCpressbrake,#hydrid, #servopump,#servomotor

-

-

Name:*

-

Email:*

-

Phone:*

-

Company Name:

-

Comments:*Note:HTML is not translated!