JCO-10000T12500 Pipe Making Machine

Parameters

|

|

Specification |

Parameter |

|

Remark |

|

|

1 |

Rated force |

100000 |

KN |

|

|

|

2 |

Length of table |

12500 |

mm |

|

|

|

3 |

Distance between columns |

12800 |

mm |

|

|

|

4 |

Bending length |

8000-12200 |

mm |

|

|

|

5 |

Max.daylight |

2580 |

mm |

Max.Φ1800 |

|

|

6 |

Side throat depth |

2000 |

mm |

|

|

|

7 |

Beam stroke length |

500 |

mm |

|

|

|

8 |

Max. V of die |

800 |

mm |

|

|

|

9 |

Number of cylinders |

6 |

piece |

|

|

|

11 |

Power of servo motor |

6×90 |

KW |

INNVOICE |

|

|

12 |

Capacity of pump |

6×160 |

L/min |

|

|

|

13 |

Max. pressure of hydraulic |

25.5 |

MP |

|

|

|

14 |

Beam speed |

Approaching |

60 |

mm/s |

|

|

Bending |

6 |

mm/s |

|

||

|

Returning |

60 |

mm/s |

|

||

|

15 |

Overall dimension |

Length |

16200 |

mm |

|

|

Width |

5800 |

mm |

Without feeder |

||

|

Height |

10260 |

mm |

Overground |

||

|

5800 |

|

Underground |

|||

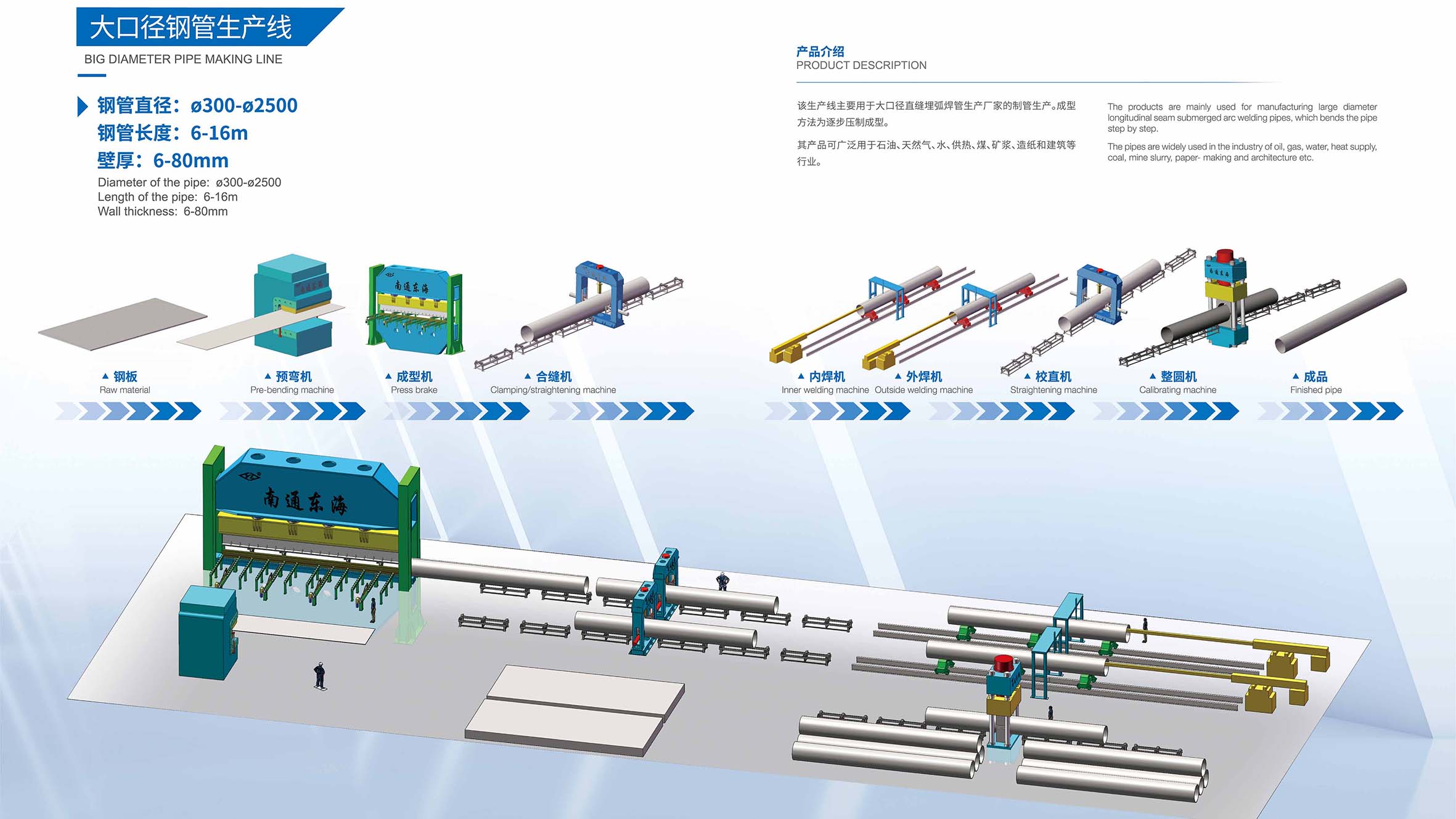

Features

▲ highly productive, accurate to make the small diameter but thick wall pipe

▲close loop proportional hydraulics for beam synchronization

▲REXROTH highly precise proportional valve to control accurate beam movement

▲ accurate & fine beam position control by micro limit switch.

▲CNC controlled front feeder/back gauge

▲motorized side discharger

▲moviable lower die to bend the end of the plate

▲variable-V die to suit to different thickness plate

▲FAGOR lineal scale

▲servo motor

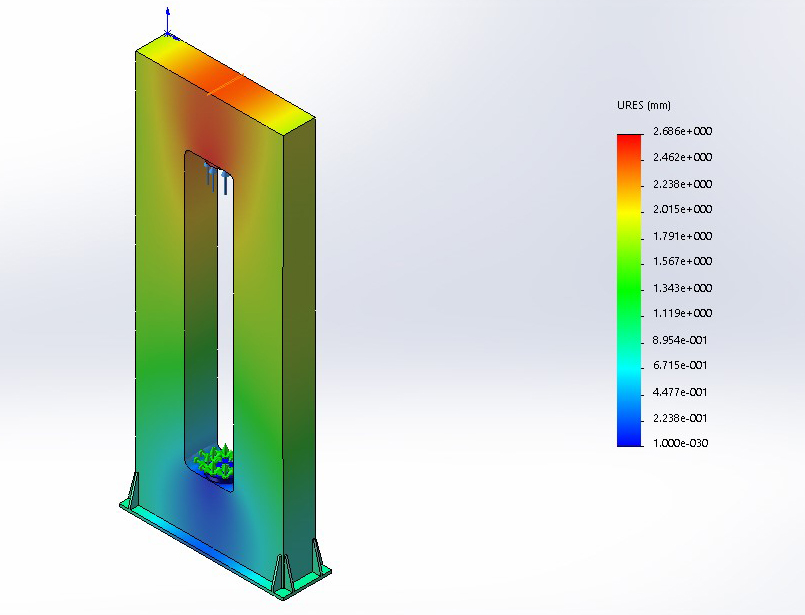

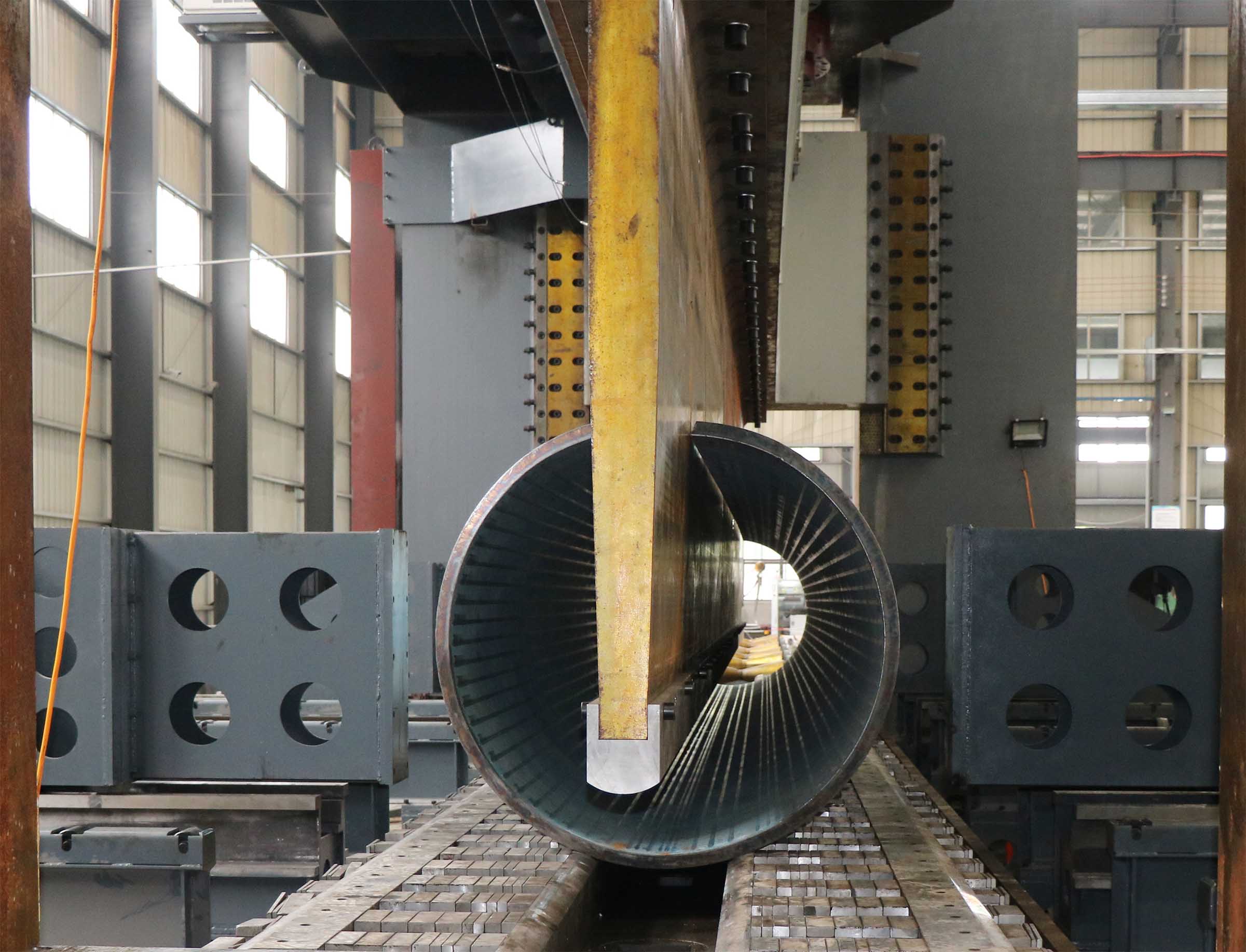

Main frame

--Hydraulic system

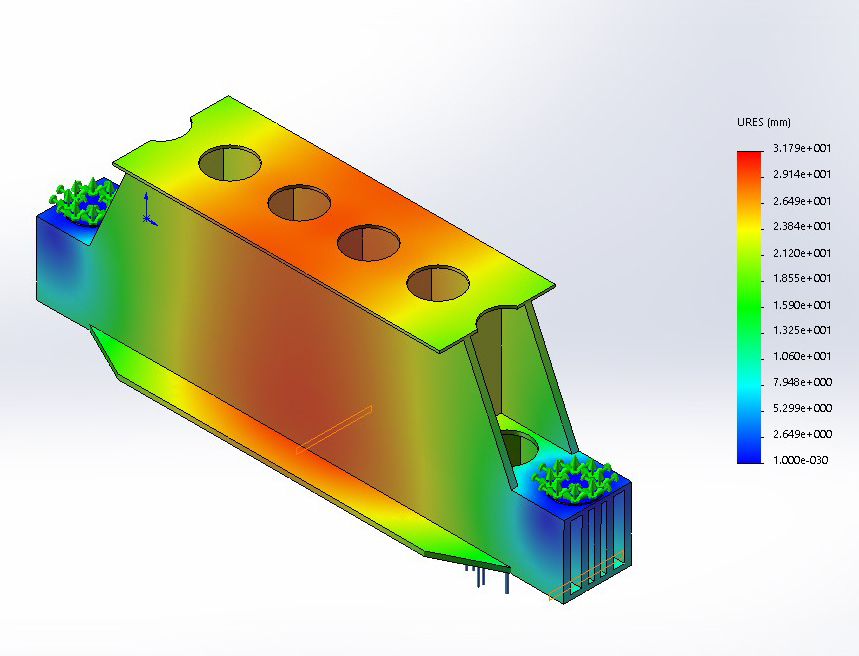

Cylinder

Cylinder

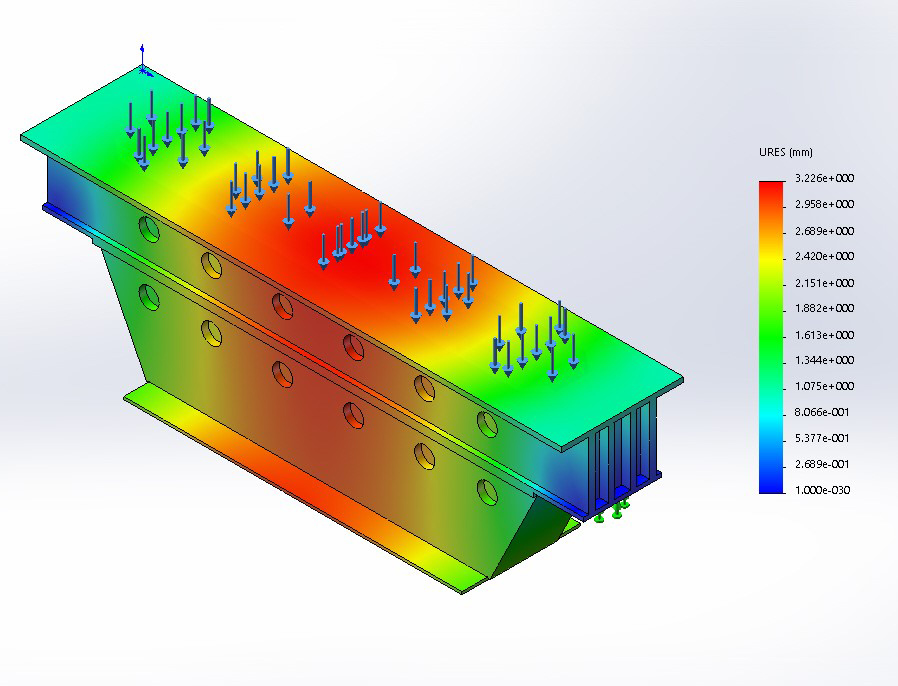

Variable lower die

Variable lower die, Max.V=800mm

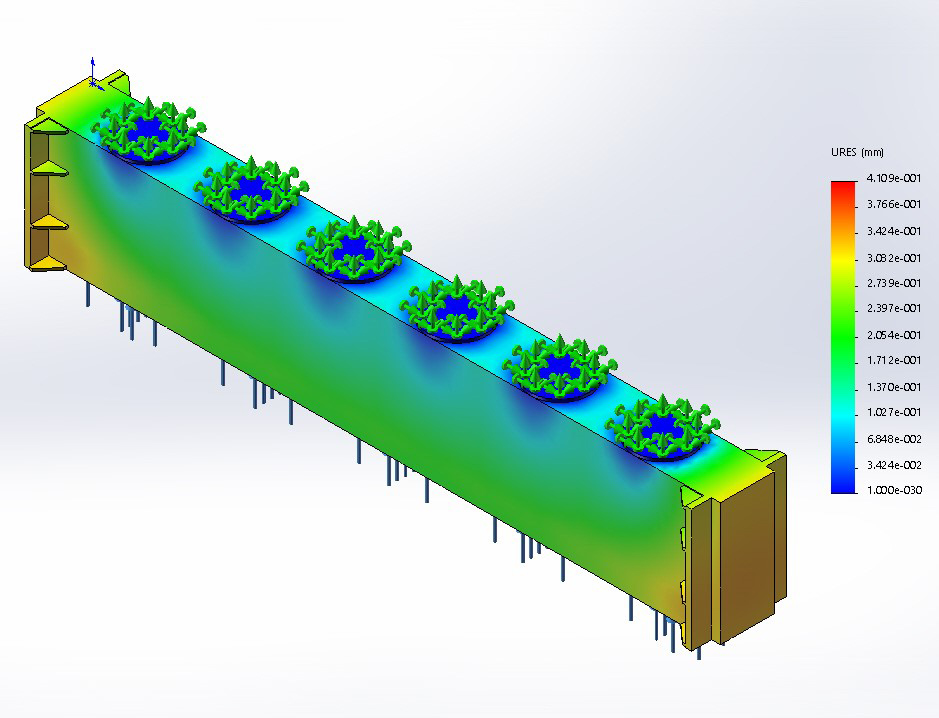

Movement die

The die can move in horizontal, to pre-bend the end of the plate.

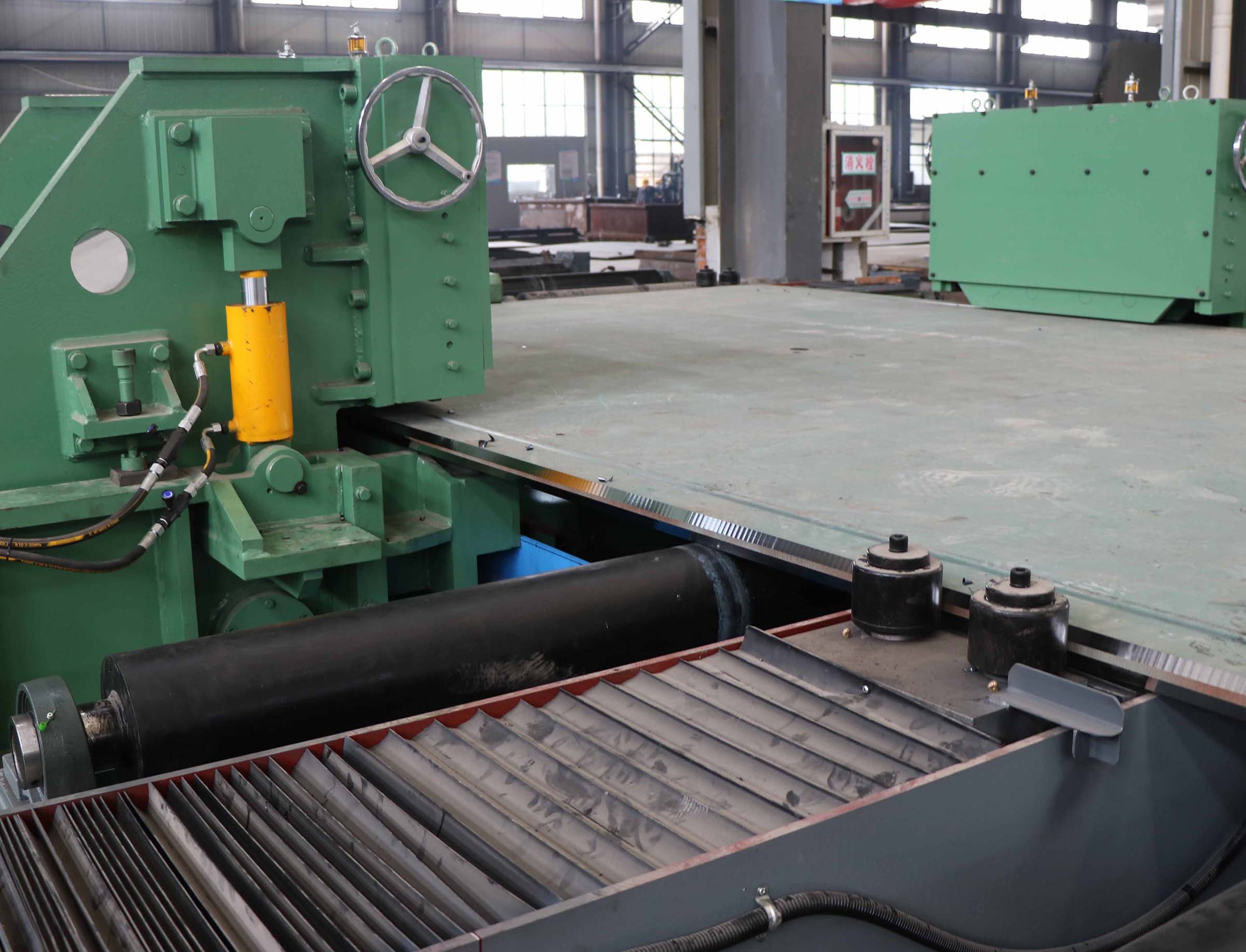

CNC controlled front feeding system

Max.feeding range:6000mm

CNC controlled back gauge

Max.feeding range:6000mm

Motorized feeding pathway

Side discharger

Optional

--Edge chamfering

--Clamping/straightening

--Inner welding machine

--Out welding machine

Pipe making machine, press brake, clamping, straightening, innwer welding, out welding

-

-

Name:*

-

Email:*

-

Phone:*

-

Company Name:

-

Comments:*Note:HTML is not translated!